NOT FOR RELEASE, PUBLICATION OR DISTRIBUTION, IN WHOLE OR IN PART, DIRECTLY OR INDIRECTLY, IN OR INTO THE UNITED STATES, AUSTRALIA, CANADA, HONG KONG, JAPAN OR ANY JURISDICTION IN WHICH SUCH RELEASE, PUBLICATION OR DISTRIBUTION WOULD BE UNLAWFUL. THIS ANNOUNCEMENT DOES NOT CONSTITUTE AN OFFER OF ANY OF THE SECURITIES DESCRIBED HEREIN.

Aker ASA (100% owner of Aker Capital AS) (“Aker”) and bp p.l.c (100% owner of BP Exploration Operating Company Ltd) (“BP”) (jointly the “Sellers”) have retained J.P. Morgan AG and Pareto Securities AS as Joint Global Coordinators and Joint Bookrunners (collectively referred to as the «Managers») to explore a potential block sale of existing shares in Aker BP ASA (“Aker BP” or the «Company») through a private placement (the “Offering”).

The Sellers are contemplating selling approximately 18,000,000 shares in the Company, representing approximately 5% of the shares outstanding in the Company, through an accelerated bookbuilding process. Aker and BP are expected to participate in the Offering pro-rata to their current holdings in the Company, i.e. approx. 57% of the shares are offered by Aker and approx. 43% of the shares are offered by BP. The free float in the Company will increase from 30% to approximately 35% if the Offering is completed. The Sellers reserve the right, at their own discretion, to sell fewer shares or no shares at all in the Offering.

The Offering will commence immediately following the publication of this announcement (10 November 2021) and will close no later than 11 November 2021 at 08:00 CET. Please note that the Offering may close earlier or later at the discretion of the Sellers. The Offering is expected to be priced and allocated before 09:00 CET on 11 November 2021 (T). The settlement of the Offering will be conducted on a normal delivery-versus-payment basis (DVP T+2).

Aker and BP currently control 144,049,005 and 108,021,449 shares in the Company respectively, representing approximately 40% and 30% of the shares outstanding in the Company. The Sellers will enter into a 6-month lock-up with the Managers following the completion of the Offering for any of the shares the Sellers currently hold in the Company which are not sold as part of the Offering, subject to certain exemptions.

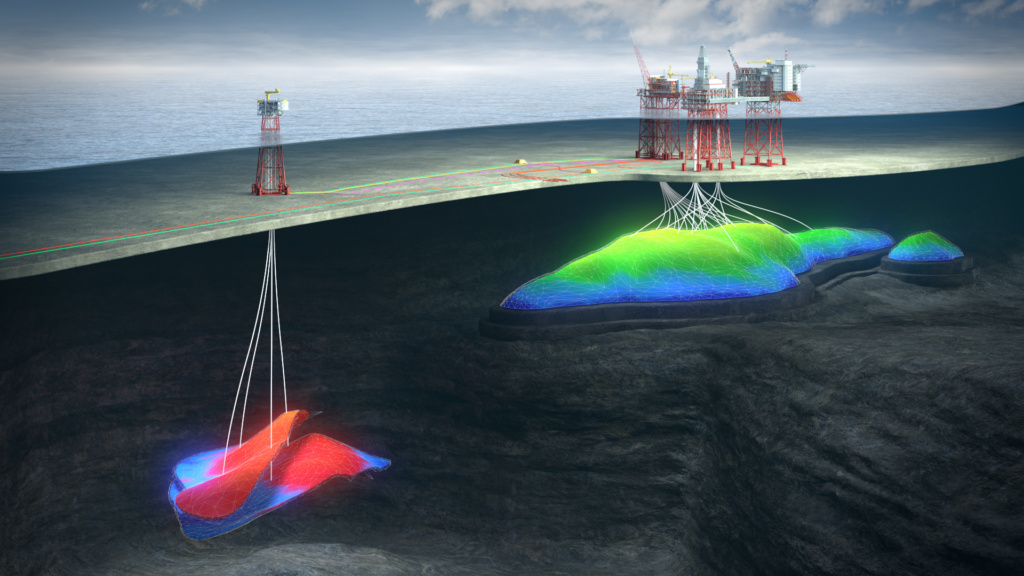

Since the creation of Aker BP in 2016, the company has pursued a successful organic and inorganic growth strategy offering attractive shareholder distributions and value creation combined with an investment grade rated balance sheet. Aker BP is a pure-play O&G company with industry-leading low emissions and low-cost operations enabled by digitalization. The company has strong production growth, a robust balance sheet and deliver attractive returns. After the potential block sale, Aker and BP will remain committed to Aker BP.

“Aker has a large portfolio with a variety of investments across different sectors whereas Aker BP represented 50% of Aker’s gross asset value per 3Q 2021. Aker BP is, and will remain, a core holding in Aker’s portfolio. The aim of the Offering is however to balance Aker’s portfolio by freeing up liquidity, diversifying and continue growing the portfolio. If the Offering is completed, Aker BP will remain the largest investment in Aker’s portfolio and Aker will remain the largest shareholder in Aker BP”, said Øyvind Eriksen, President and CEO of Aker ASA.

Bernard Looney, BP chief executive said: “Aker BP has established itself as an undoubted Norwegian success story, with its value increasing significantly over the past five years. This transaction will enable bp to realise some of the considerable value Aker BP has already generated while remaining committed to its ongoing success and value creation for shareholders. Consistent with our long-standing track-record of active portfolio management, these divestment proceeds will be expected to further strengthen bp’s balance sheet and support our ongoing buyback commitment.”

The minimum order and allocation in the Offering have been set to the NOK equivalent of EUR 100,000. The Managers may, however, offer and allocate an amount below the NOK equivalent of EUR 100,000 in the Offering to the extent exemptions from prospectus requirements, in accordance with Regulation (EU) 2017/1129, are available.

Kjell Inge Røkke, the chairman of the board of directors in Aker ASA and the ultimate majority owner of Aker ASA, is a member of the board of directors in Aker BP. Øyvind Eriksen, the President and CEO of Aker, is the chairman of the board of directors in Aker BP. Murray Auchincloss, the CFO of BP Plc and Kate Thomson, SVP Finance OB&C of BP Plc, are members of the board of directors in Aker BP.

For more information about the Offering please contact one of the Managers:

J.P. Morgan AG

+49 69 71240

Pareto Securities AS

+47 22 87 87 50

This information is considered to include inside information pursuant to the EU Market Abuse Regulation article 7 and is subject to the disclosure requirements pursuant to section 5-12 of the Norwegian Securities Trading Act. This stock exchange announcement was published by Kaja Fürst, Treasury Manager at Aker BP ASA, on 10.11.2021 at 16:50 (CET).

Important Notices

This announcement is not and does not form a part of any offer to sell, or a solicitation of an offer to purchase, any securities of the Company. The distribution of this announcement and other information may be restricted by law in certain jurisdictions. Copies of this announcement are not being made and may not be distributed or sent into any jurisdiction in which such distribution would be unlawful or would require registration or other measures. Persons into whose possession this announcement or such other information should come are required to inform themselves about and to observe any such restrictions.

The securities referred to in this announcement have not been and will not be registered under the U.S. Securities Act of 1933, as amended (the «Securities Act»), and accordingly may not be offered or sold in the United States absent registration or an applicable exemption from the registration requirements of the Securities Act and in accordance with applicable U.S. state securities laws. The Company does not intend to register any part of the offering or its securities in the United States or to conduct a public offering of securities in the United States.

In any EEA Member State, this communication is only addressed to and is only directed at qualified investors in that Member State within the meaning of the Prospectus Regulation, i.e., only to investors who can receive the offer without an approved prospectus in such EEA Member State. The expression «Prospectus Regulation» means Regulation (EU) 2017/1129 as amended together with any applicable implementing measures in any Member State.

This communication is only being distributed to and is only directed at persons in the United Kingdom that are “qualified investors” within the meaning of the Prospectus Regulation as it forms part of English law by virtue of the European Union (Withdrawal) Act 2018 and that are (i) investment professionals falling within Article 19(5) of the Financial Services and Markets Act 2000 (Financial Promotion) Order 2005, as amended (the «Order») or (ii) high net worth entities, and other persons to whom this announcement may lawfully be communicated, falling within Article 49(2)(a) to (d) of the Order (all such persons together being referred to as «relevant persons»). This communication must not be acted on or relied on by persons who are not relevant persons. Any investment or investment activity to which this communication relates is available only for relevant persons and will be engaged in only with relevant persons. Persons distributing this communication must satisfy themselves that it is lawful to do so.

Matters discussed in this announcement may constitute forward-looking statements. Forward-looking statements are statements that are not historical facts and may be identified by words such as «believe», «expect», «anticipate», «strategy», «intends», «estimate», «will», «may», «continue», «should» and similar expressions. The forward-looking statements in this release are based upon various assumptions, many of which are based, in turn, upon further assumptions. Although the Sellers believe that these assumptions were reasonable when made, these assumptions are inherently subject to significant known and unknown risks, uncertainties, contingencies and other important factors which are difficult or impossible to predict and are beyond their control.

By their nature, forward-looking statements are subject to numerous factors, risks and uncertainties that could cause actual outcomes and results to be materially different from those projected. Readers are cautioned not to place undue reliance on these forward-looking statements. Except for any ongoing obligation to disclose material information as required by the applicable law, the Sellers do not have any intention or obligation to publicly update or revise any forward-looking statements after they distributes this announcement, whether to reflect any future events or circumstances or otherwise.

Neither of the Managers nor any of their respective affiliates makes any representation as to the accuracy or completeness of this announcement and none of them accepts any responsibility for the contents of this announcement or any matters referred to herein.

This announcement is for information purposes only and is not to be relied upon in substitution for the exercise of independent judgment. It is not intended as investment advice and under no circumstances is it to be used or considered as an offer to sell, or a solicitation of an offer to buy any securities or a recommendation to buy or sell any securities in the Company. Neither the Managers nor any of their respective affiliates accepts any liability arising from the use of this announcement.