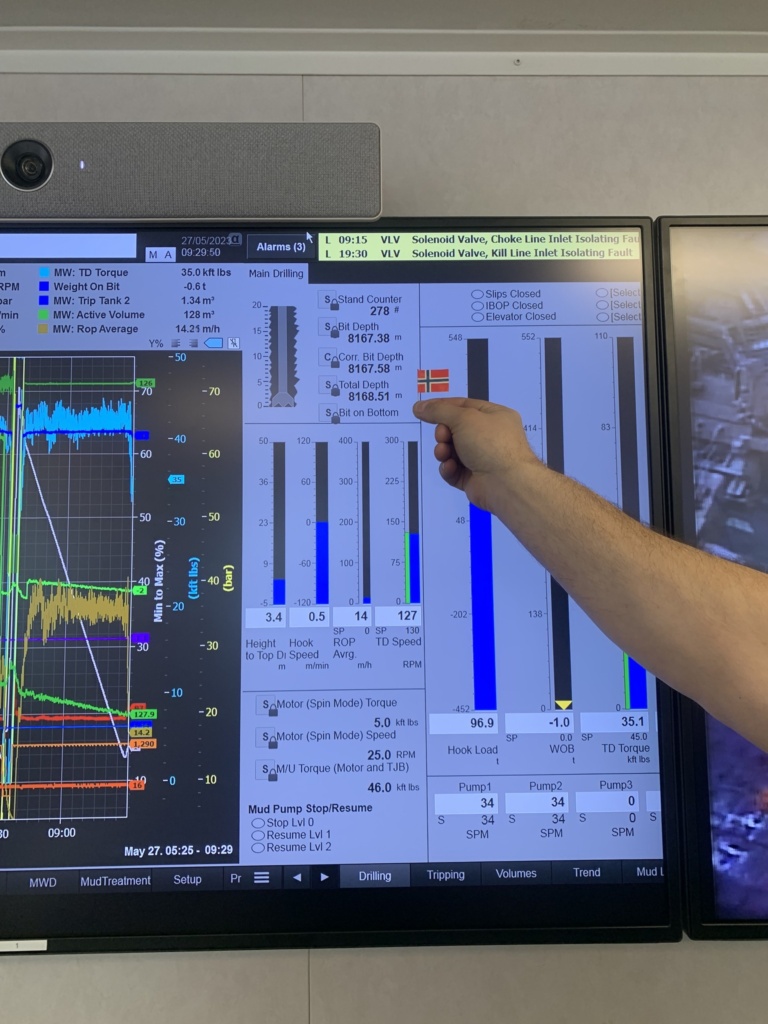

When the Øst Frigg Beta/Epsilon wildcat well reached its target depth, the team had drilled 8168 metres. As it made its way horizontally through the reservoir, the value of Yggdrasil increased metre by metre − in what is Norway’s longest ever exploration well.

Preliminary calculations of the Øst Frigg Beta/Epsilon discovery show 53-90 million recoverable barrels of oil equivalents (link to the NPD notice). The overall resources in the Yggdrasil area have increased to more than 700 million barrels.

«We’re talking about a total increase in resources of approximately ten percent. This means further improved profitability in the development and increased value creation from Yggdrasil. Many years of very good work over several years is behind this discovery from the team. I’m very proud of what we’ve just delivered,» says SVP Yggdrasil Lars Høier.

Aker BP first reported the discovery on Thursday, 25 May. At that point, the drilling was nearly complete, and it was clear that the company had made a significant oil discovery. On Friday, the projected volume was increased further.

Gas already produced

Øst Frigg consists of two structures, Alpha and Beta. This is a gas discovery from the 1970s with ten metres of oil under the gas. The gas was produced in the 1980s and 1990s by Elf, while the oil remained untouched.

«This means that we’ve got more than 250 million barrels of proven oil, yet to be produced, in the middle of an area we’re going to develop. We had to get to the bottom of this. Where had the oil gone?» asks Subsurface manager Tor-Ole Jøssund.

The hunt for the Øst Frigg oil got started in early 2022. A sidetrack to Øst Frigg Alpha was drilled from the Grefsenkollen well.

«The result showed a bit of oil on top, and some oil trapped under a barrier, but it was too spread out to recover. This wasn’t the result we were hoping for,» Jøssund says. The subsurface team worked out a plan to drill horizontally in Beta and also included Epsilon.

The Øst-Frigg Beta/Epsilon wildcat well has a vertical main track and three horizontal sidetracks. The Scarabeo 8 rig started drilling in april. The first sidetracks were drilled in the Beta structure to prove oil and appraise the discovery. The sidetrack to Epsilon was the last one.

Most of the Beta well was used to reach the Epsilon structure. The last casing was landed in the reservoir and drilling of the horizontal section towards Epsilon started. The results were promising, and the drilling continued towards the Gamma structure. Over a period of two weeks, the team drilled more than 6000 metres, openhole and horizontally, in the reservoir to collect geological data.

Six kilometres in the reservoir

The Øst-Frigg Beta/Epsilon wildcat well has a vertical main track and three horizontal sidetracks. The Scarabeo 8 rig started drilling in april. The first sidetracks were drilled in the Beta structure to prove oil and appraise the discovery. The sidetrack to Epsilon was the last one.

Most of the Beta well was used to reach the Epsilon structure. The last casing was landed in the reservoir and drilling of the horizontal section towards Epsilon started. The results were promising, and the drilling continued towards the Gamma structure. Over a period of two weeks, the team drilled more than 6000 horizontal open hole metres in the reservoir to collect geological data.

«Drilling six kilometres horizontally is a significant achievement. It requires precision and the ability to constantly assess risk against reward based on a continuous stream of data, as exploration wells have higher uncertainty than regular wells. We’re also doing this with a rig that’s new to Aker BP,» says Hanna Tronstad, drilling superintendent.

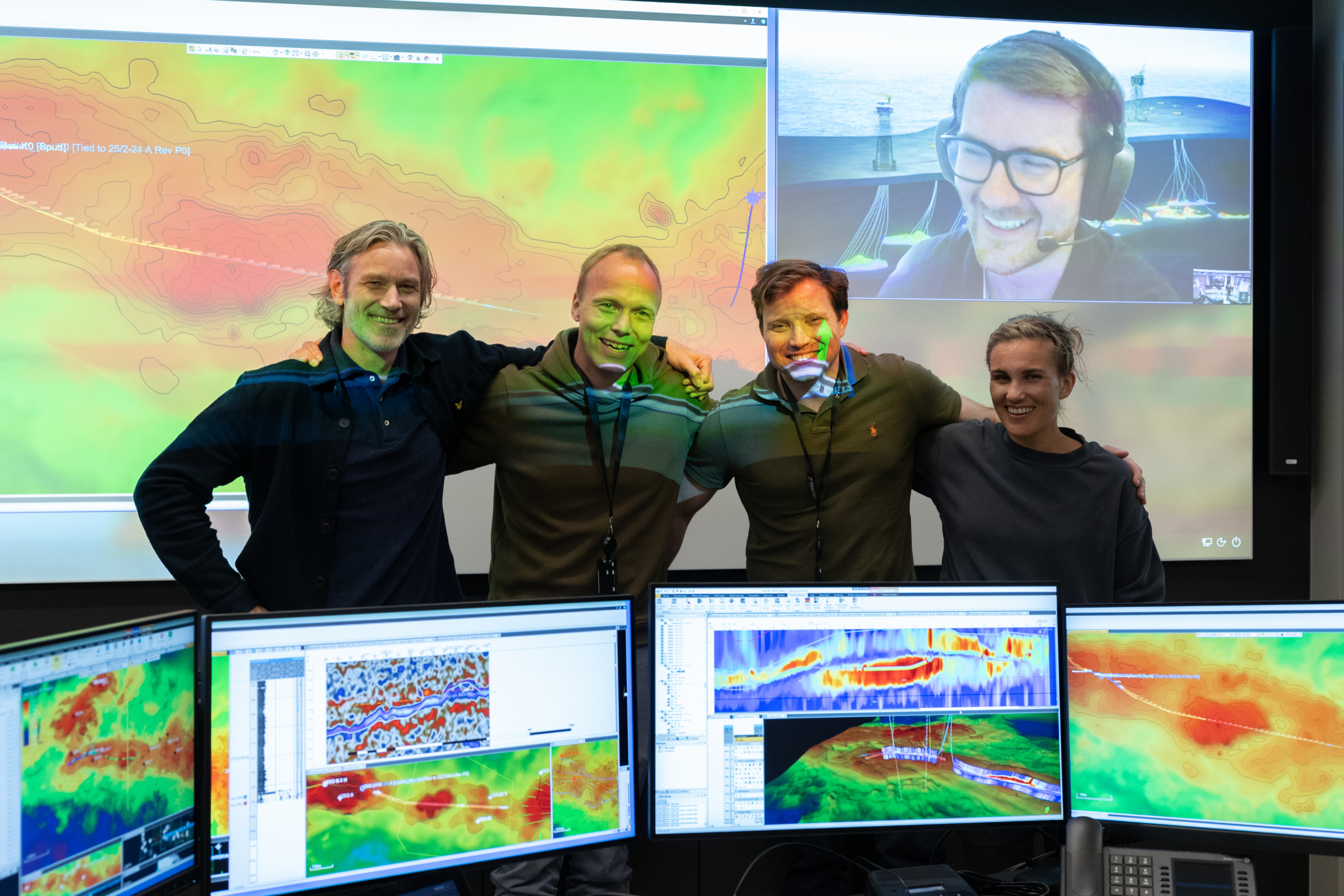

The drilling operation was monitored around the clock from Aker BP’s new drilling operations centre in Trondheim. So-called geosteering allowed the team to optimise well placement in the oil-bearing layer. This is possible through using a resistivity map that was developed based on measurements from tools downhole.

«And this is what makes this wildcat well unique. We’re able to process data quickly as we go during the operation, secure lessons learned and materialise the upside. We’re able to do this safely and efficiently based on high-quality planning and implementation. This record wouldn’t have been possible without a really good One Team mentality across departments in Aker BP. We succeeded through enormous determination in the team, good cooperation with suppliers, and particularly thanks to a solid subsurface department that challenge us,» Tronstad says.

Collected valuable data

Large volumes of data were collected while drilling the wildcat well. Along with a planned geopilot on Frigg Gamma Delta later this year, this will be very important in further well planning in the Yggdrasil development.

«Now we’ve proven that we can drill horizontally in the Frigg formation, and that we can drill over very long distances. Aker BP is planning 55 wells in the Yggdrasil area. Drilling is scheduled to start in 2025, and we’ll be spending the years leading up to this ensuring efficient planning and implementation of the production wells, many of which are horizontal,» Tronstad says.

Øst Frigg Beta/Epsilon is described in the plan for development and operation as potential additional resources for Yggdrasil. The Yggdrasil area has a significant degree of flexibility and is designed to be a hub for future discoveries and fields like this. Aker BP will now further mature the discovery.

«Along with our partners Equinor and PGNIG Upstream Norway, we will continue to actively explore the area through additional exploration wells and appraisal wells over the next years,» concludes VP Exploration Olav Antonio Blaich.