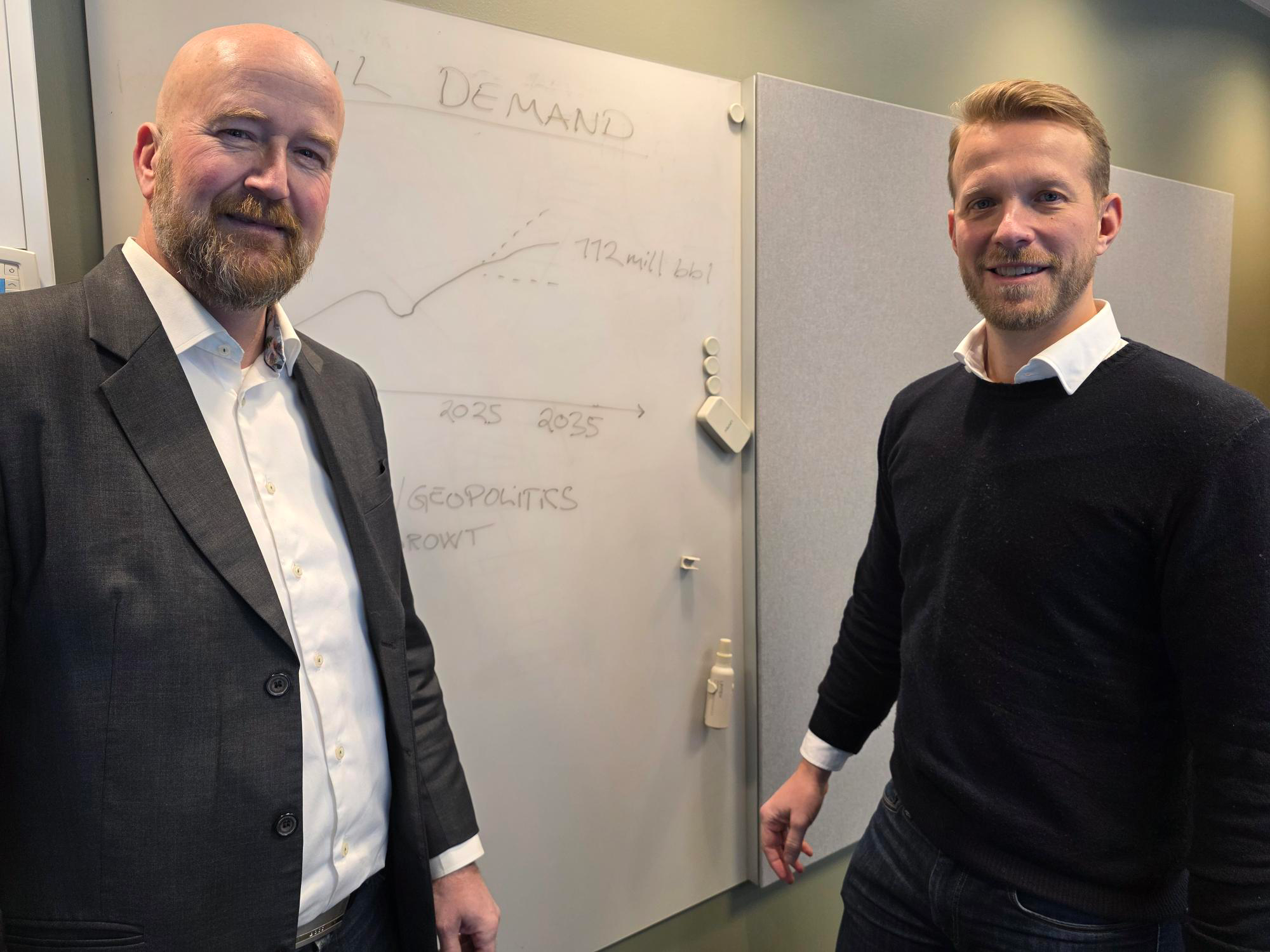

Aker BP projects that global oil demand will continue to grow over the coming decade, reaching around 112 million barrels per day by 2035.

In Aker BP’s base case, global oil demand is expected to increase from roughly 105 million barrels per day today to approximately 112 million barrels per day in 2035. This equates to an average annual rise of about 0.7 million barrels per day.

It is the first time Aker BP publish a long-term oil demand outlook. By publishing a quantified base case, Aker BP contributes to the strong analytical tradition in the industry, complementing peers’ scenario work by openly sharing a comprehensive longterm demand study.

The work is conducted by Chief Economist Torbjørn Kjus, which leads the company’s energy market forecasting efforts, and the Markets & Strategic Insights team led by Jostein Magerøy. Modelling is supported by demandside tools from Rystad Energy, used with permission.

Aker BPs oil demand outlook reflects powerful structural forces as population growth, rising incomes, expanding mobility, and increasing materials consumption. All contributing to resilient longterm demand across multiple regions and sectors.

Key drivers include:

- Road Transport: Demand peaks toward 2030 but remains resilient, with consumption in 2035 still higher than today. Efficiency gains and electrification temper growth but do not lead to a rapid decline.

- Petrochemicals: One of the strongest growth engines, driven by rising global demand for materials, plastics, and chemical products.

- Aviation: Increasing global travel and economic expansion support steady, long term consumption growth.

- Other sectors: Maritime, buildings, and industrial use remain broadly stable.

- Power generation: The only major segment showing structural decline as oil continues to be phased out of electricity production.

Aker BP’s long-term oil demand outlook also features a upside and downside scenario.

Under conditions of stronger economic growth and slower efficiency improvements, oil demand could expand more rapidly. This scenario is characterized by:

- Faster than expected aviation and petrochemical growththanexpected aviation and petrochemical growth

- More moderate policy tightening

- Delayed efficiency gains in transport and industry

The result: higher demand growth than the base case and a later peak.

In a world where climate policies accelerate and electrification expands quickly, demand growth would moderate sooner. This scenario includes:

- Faster adoption of electric vehicles

- Accelerated policy action and efficiency improvements

- Weaker macroeconomic conditions

- Potential geopolitical disruptions

Together, these factors point to lower growth and an earlier plateau in global oil demand.

Aker BP’s analysis covers 31 regions and 12 sectors, incorporating macroeconomic trends, technology shifts, policy developments, and refinedproduct demand patterns.

Growth Sectors

- Petrochemicals: Driven by rising global consumption of plastics and chemical feedstocks.

- Aviation: Supported by increasing travel demand and expanding global middle-class mobility.

- Road Transport: Approaches a peak but remains a major consumer through 2035.

Stable Sectors

- Maritime

- Buildings

- Industry: Slightly lower but largely steady.

Declining sector

- Power Generation: The primary source of structural decline as countries transition to other fuels.

With this publication, Aker BP aims to contribute constructively to the global energy dialogue by offering a consistent, transparent, and datadriven perspective on how oil demand may evolve toward 2035.