Yggdrasil is the largest ongoing oil and gas development in Norway. In close collaboration with Street Art Norway, we are now launching a major art project where contemporary street art will leave its mark on all platforms and facilities in the Yggdrasil area. The winner of the commission is one of Norway’s leading artists, graffiti and visual artist Simon Alfredo Compagnet Diaz.

An Innovative Choice of Art

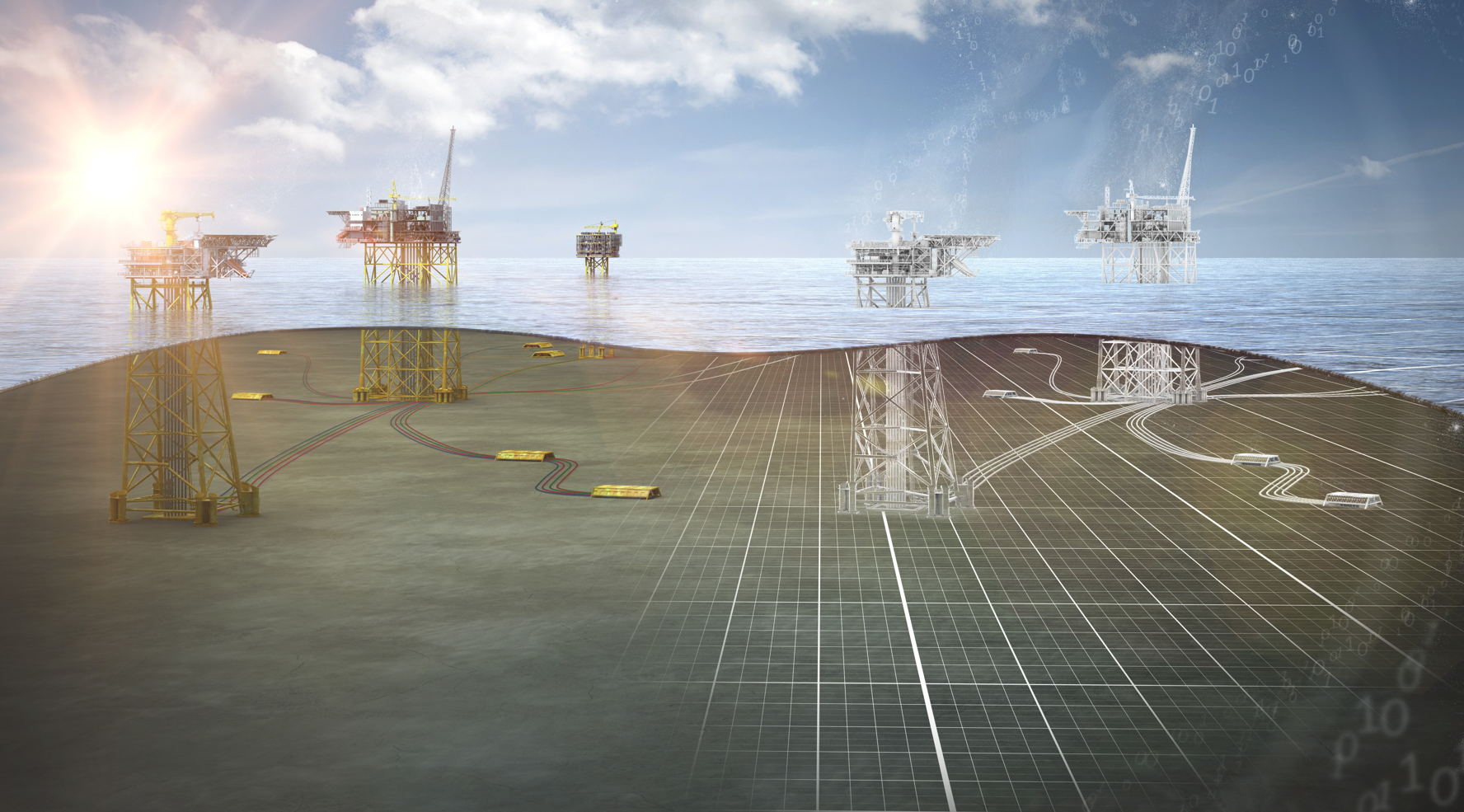

Yggdrasil is being developed with three platforms, extensive subsea infrastructure, oil and gas export, and power from shore. With Yggdrasil, we are setting a new standard for operating an oil and gas area. The entire area, which stretches nearly 60 kilometers in the North Sea, will be remotely operated from an integrated collaboration center and control room in Stavanger. The platforms will be unmanned or periodically unmanned, work will be moved from sea to land, and fewer people will be working offshore. This requires new technology, digitalization, and new ways of working.

While we are choosing the most innovative technological solutions for Yggdrasil, we have also taken an innovative and somewhat unconventional approach to its decoration.

“Through art, we want to create a common thread that ties all parts of Yggdrasil together. Our goal is for those working on our platforms and facilities to have a good working environment, and well-being and pride in one’s surroundings are incredibly important. So this art project is not just about aesthetics. It’s about identity, environment, pride – and building culture. That’s why we also listened to our employees, and they wanted street art to be part of Yggdrasil’s decoration,” says Truls Haugen, Platform Manager and Project Lead for the decoration at Aker BP.

In close collaboration with Street Art Norway, more than 20 walls have been selected – both indoors and outdoors – to be decorated across three platforms, two power-from-shore stations, and the integrated operations center in Stavanger.

One of Norway’s Leading Artists Won the Competition – “MAD WITH LONGING”

Simon Alfredo Compagnet Diaz is a graffiti and visual artist with nearly 30 years of experience in street art, graffiti, and urban contemporary art, covering everything from paintings and street art decorations to video art and concert visuals.

Diaz’s winning concept, Mad with Longing, is a visual journey that blends industrial power with human emotion – created to coexist with a high-tech workplace.

“I feel incredibly privileged to be part of what may be the largest street art/contemporary art decoration project in Europe. Being allowed to contribute to creating a good working environment for so many people over so many years is a great feeling. The employees are also involved in the process and in choosing how the final results will look. I’m really looking forward to this,” says Simon Alfredo Compagnet Diaz.

Street Art Norway is responsible for executing the project in close collaboration with Aker BP.

“We will coordinate and help carry out a major decoration project together with Aker BP and the artist. The project will also help demonstrate how street artists and street art can contribute to creating a cohesive profile and a good working environment for employees and visitors across all parts of Yggdrasil. This will be a major project for street art in many ways,” say Ola Hanø / Dino Beslic of Street Art Norway.