On June 5th, I received an incoming Teams call from the project manager for T&I in Valhall PWP-Fenris. The excitement hit instantly when I got confirmation of what I had been eagerly awaiting for the past few weeks. In true northern Norwegian fashion, I didn’t need to hear more than “Javæll, e du klar før tur?” (“Alright, are you ready for the trip?”) to realize I had been given the opportunity to join the installation of the PWP jacket and the connecting bridge to PH at Valhall.

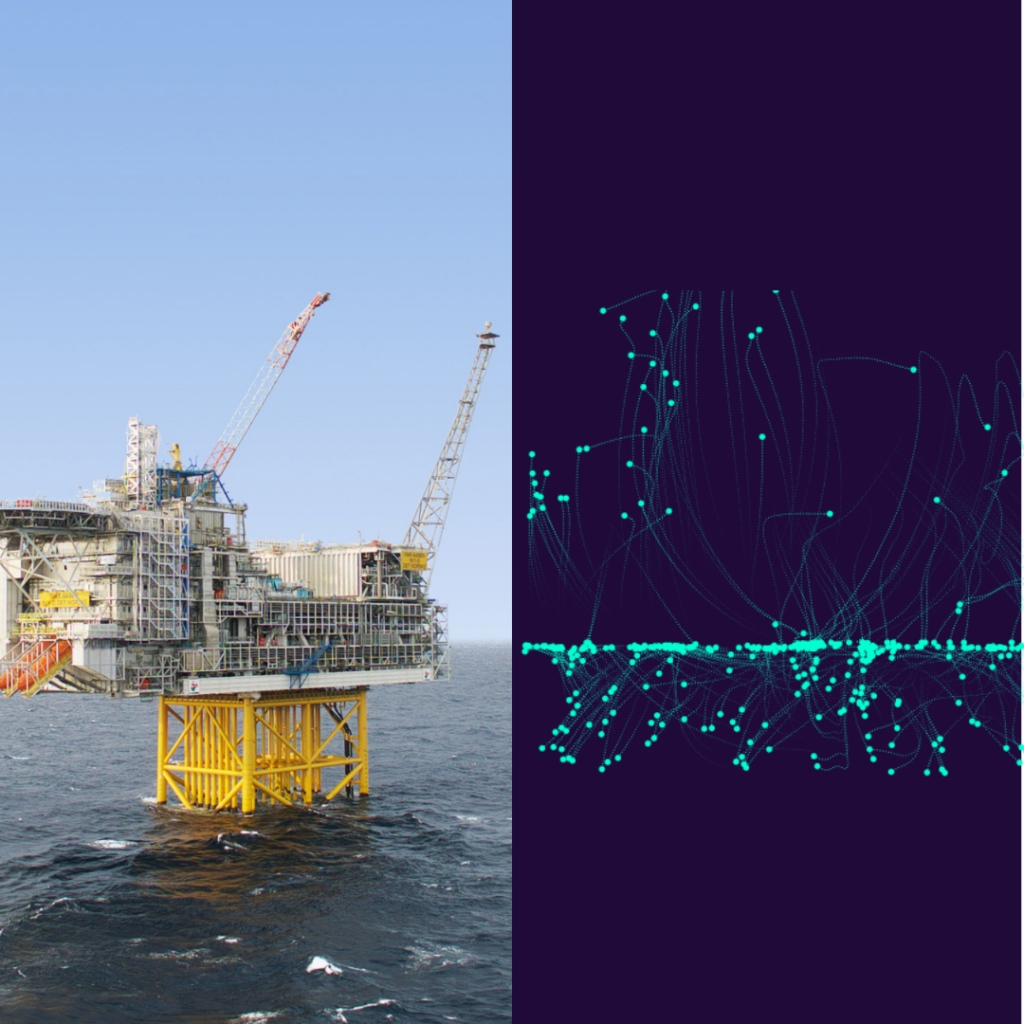

We mobilized from the Mekjarvik quay and were transported to SSCV Sleipnir by boat. It’s quite an impression to dock at one of the world’s largest lifting vessels and come face to face with such enormous dimensions. I got my first adrenaline rush during boarding, which involved being lifted by crane several tens of meters above the sea in a basket. What made it extra special was that we were lifted onto the deck just a few kilometers from my own front door in Stavanger, before Sleipnir set course for open sea.

Onboard, I took on the role of junior client representative and joined the night shift. My first thought was that it would be quiet, and I feared missing the major lifts. Luckily, I was completely wrong. “It’s during the night shift that things happen,” I was told the first night, and I can confirm that was absolutely true. My tasks included logging and preparing the daily report, which might sound trivial. On the contrary, with the goal of maximizing my learning, these tasks really forced me to understand every step of the operation. Even just taking photos for the report meant I had to be present on deck when things happened, giving me the chance to speak directly with the professionals doing the work. It was incredibly educational.

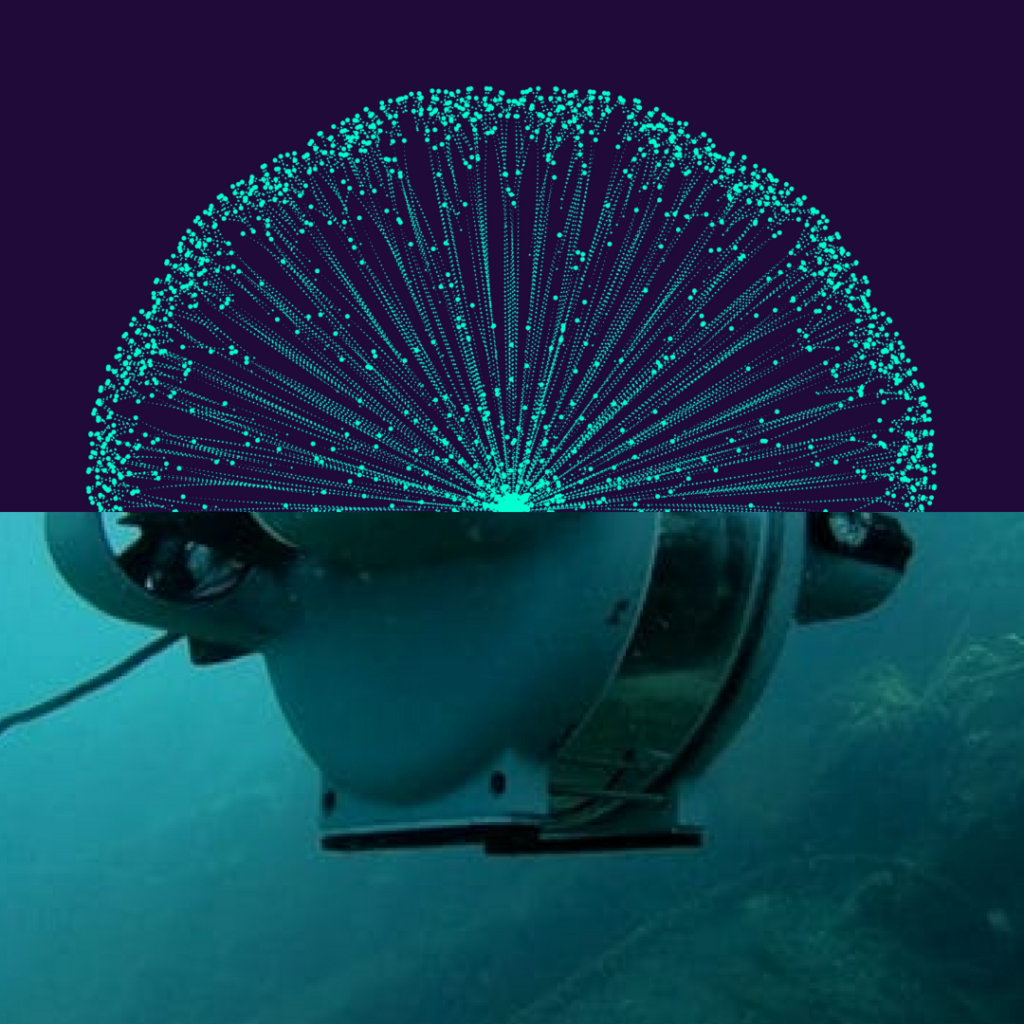

The operation offered a wide range of experiences. Among them was piling. I couldn’t imagine how one could drive gigantic steel pipes 45 meters into the ground. It turned out the principle of “hammering a nail” still applies, you just need a big enough hammer. I gained insight into aspects like pile sway, meaning the pile swings more with increasing wave height. This is important to consider when the hammer strikes with energy equivalent to a 3-ton car at 160 km/h. It’s like with a nail, it breaks if you hit too hard when it’s slightly tilted. Beyond the technical aspects, I also felt the seriousness in meetings with Heerema when things didn’t go quite as planned. At the same time, there was room for lighter moments, like feeling part of an American action movie when the ROV pilots from Oceaneering consistently confirmed commands with a crisp “Roger that.”

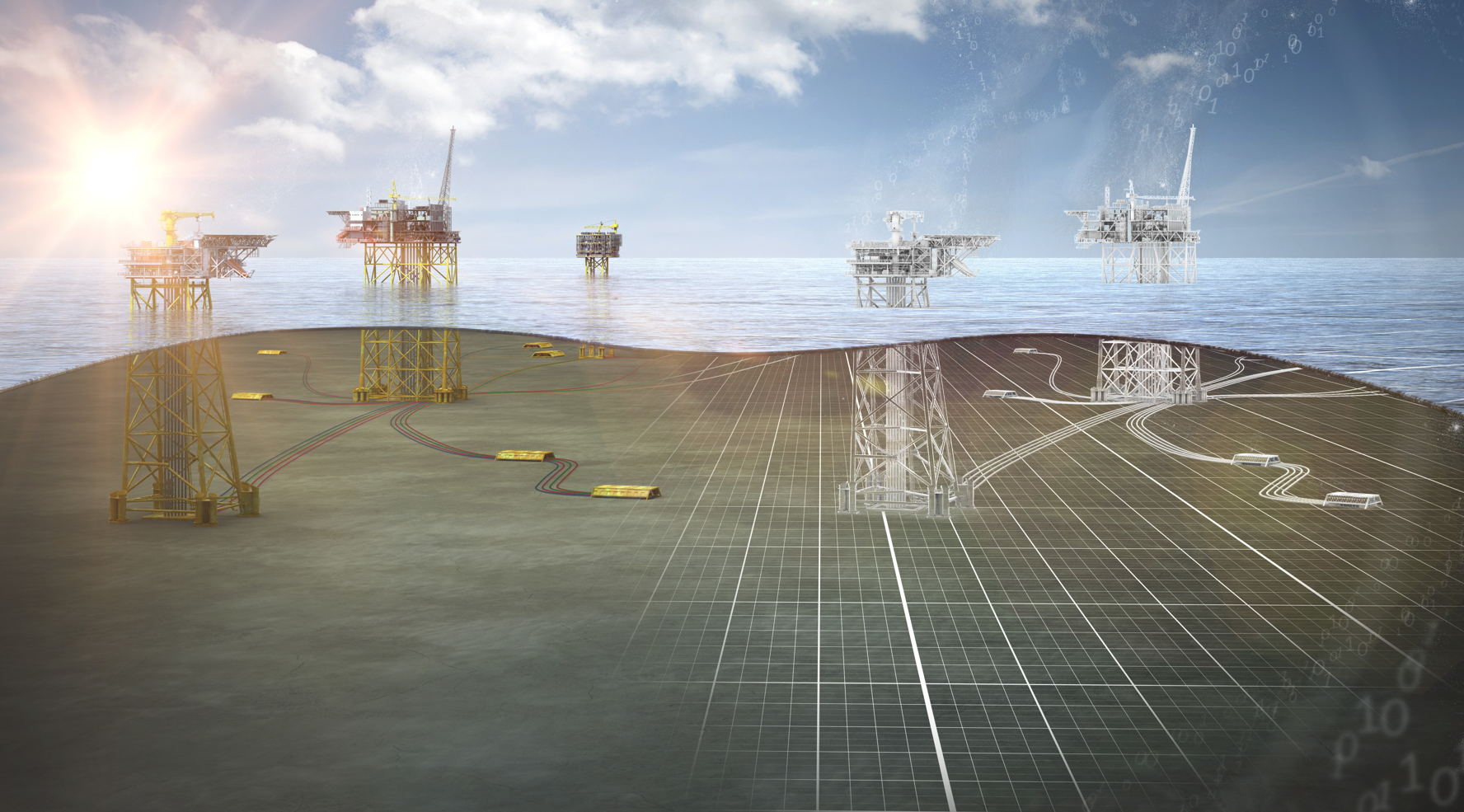

The biggest highlights were the set-down of the jacket and the bridge, both of which happened while I was on duty. Seeing the bridge connect new infrastructure to the existing was a moment I’ll never forget.

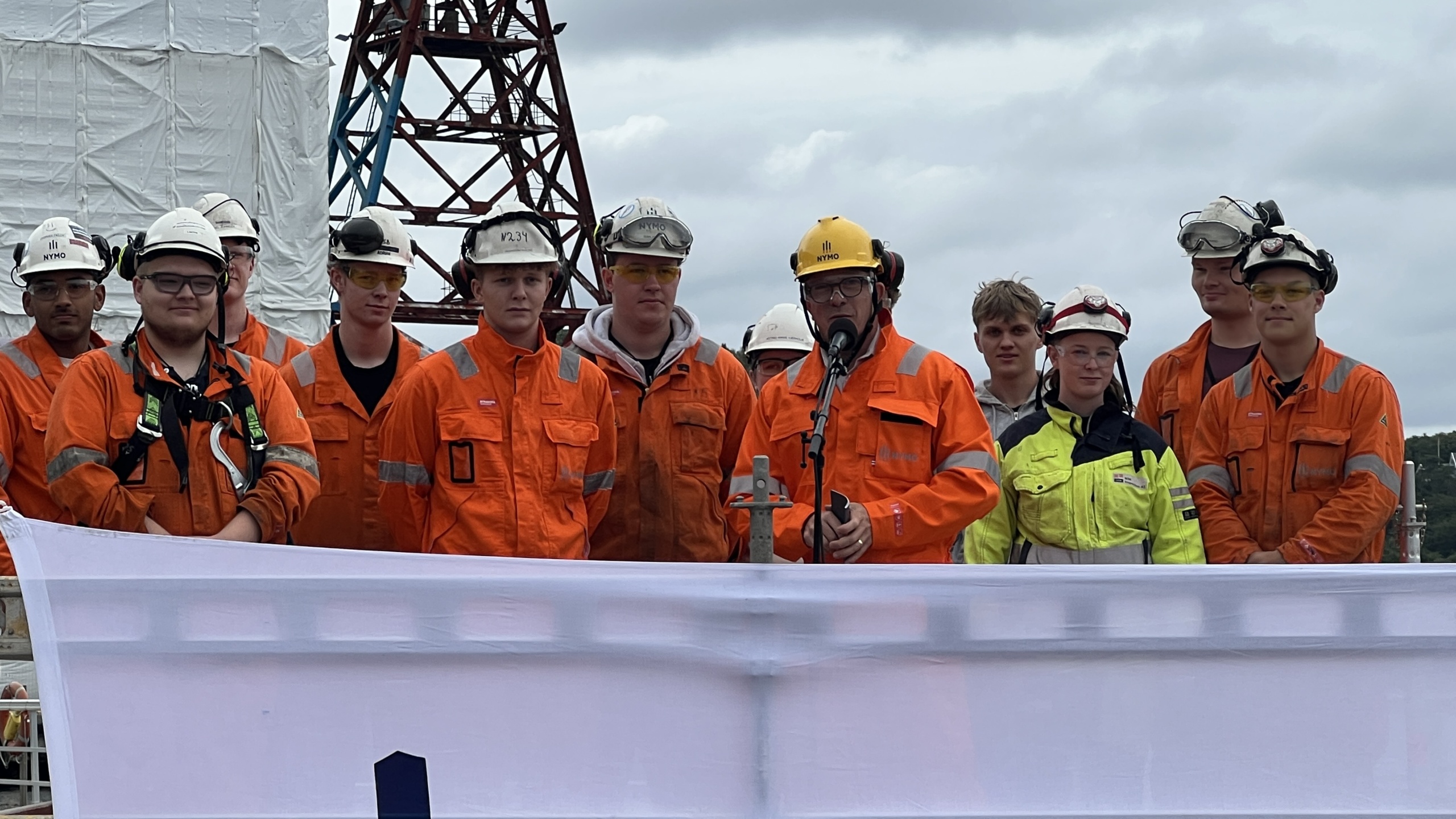

For a graduate nearing one year in the company, this was a major experience. Since my first day, I’ve heard that “it’s you young and promising ones we need to invest in.” It’s one thing to say it, another to actually send someone out. It proves that Aker BP is a company that invests in young people and has its eyes set on the future. I’ve had the opportunity to be part of many things this past year, and this trip was the highlight. What an incredible learning experience it is to be out in the field—and above all, what a huge motivation it gives for further development.

Thank you for the trip, and thank you for the experience.

Kristian Birkeland, Graduate Project Engineer