Operator Aker BP and partners report that production has started from the first Ærfugl phase 2 well in the Norwegian Sea – three years ahead of the original plan.

“The acceleration of production from Ærfugl Phase 2 means increased value creation for the Ærfugl joint venture, the supplier industry and the Norwegian society in the form of increased revenues. Thus I’m very pleased to mark this milestone. However the good news are offset by the fact that we are facing a global crisis that none of us have experienced before. Investments and explorations activities offshore Norway are put on hold. Tens of thousands of employees in our industry are currently at risk, says Kjetel Digre, SVP Operations & Asset Development in Aker BP.

As a respond to the dramatic change in the market situation, Aker BP has stopped all non-sanctioned projects, including the Hod redevelopment project in the Valhall area which was just about to be sanctioned prior to the dramatic turmoil.

“It is clear that the industry’s proposal for temporary adjustments in Norway’s tax regime to improve the industry’s cash flow in the short run – without reducing the total tax payments in the long run – will result in increased activity and new investment opportunities offshore Norway within the next 12 – 24 months,” adds Digre.

Optimized value creation

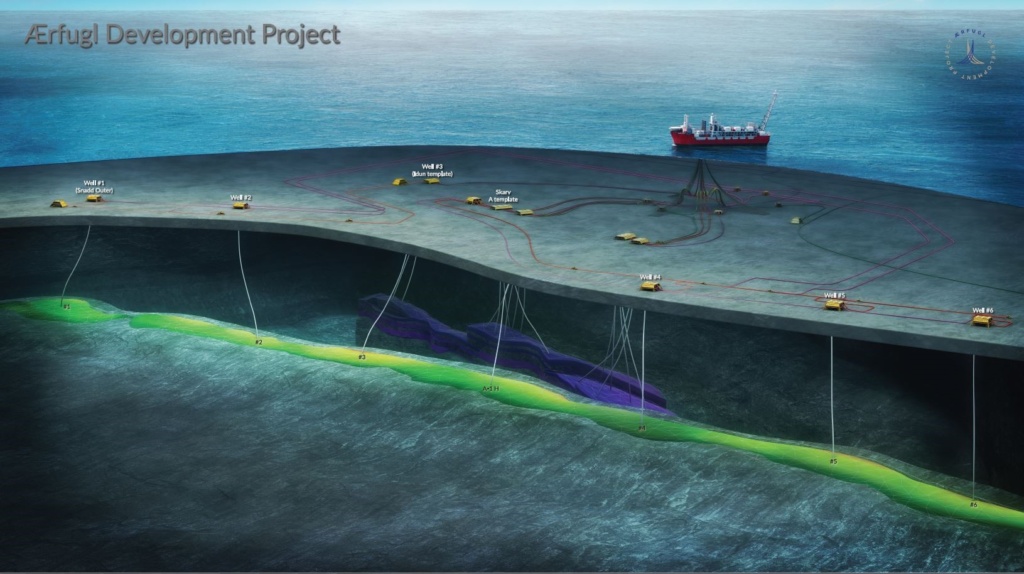

The Ærfugl field produces via Skarv FPSO approximately 210 km west of Sandnessjøen. It is one of the most profitable development projects on the Norwegian shelf with a break-even price of around USD 15 per barrel (converted from gas).

«The Ærfugl field development is adding five years lifetime extension to the Skarv FPSO and is an important part of the area development and value creation in the area, though the profitability will be dramatically reduced in the current oil price environment,” says Ine Dolve, VP Operations & Asset Development in the Skarv area.

The Plan for Development and Operation (PDO) for both phases was approved by the Ministry of Petroleum and Energy in April 2018. Phase 1, which develops the southern part of the Ærfugl field, consists of three new wells and will start-up in late 2020.

Phase 2 consists of an additional three wells in the northern part of the field. The original plan for start-up was 2023. Due to proceeded work to increase gas capacity on Skarv FPSO, the Ærfugl project team optimized the phase 2 scope and identified existing infrastructure to host the first “phase 2 well”.

In early November 2019 operator Aker BP and partners Equinor, Wintershall DEA and PGNiG approved the final investment decision (DG3) for Ærfugl Phase 2, which led to today’s announcement. The remaining two “phase 2 wells” will come on stream in 2021.

Excellent performance by three alliances

Reorganizing the value chain through strategic partnerships and alliances is an important part of Aker BP’s strategy.

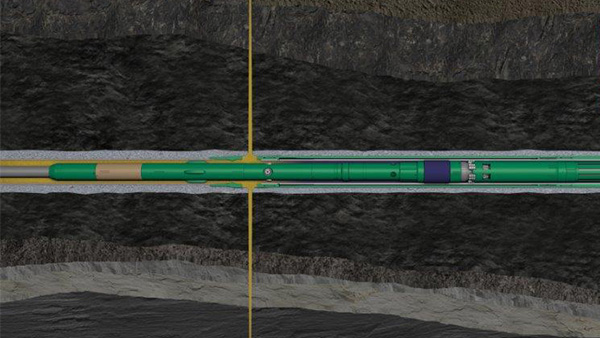

“The Subsea alliance between Aker BP, Subsea 7 and Aker Solutions has demonstrated substantial improvements and increased value creation over several years. Now we see excellent deliveries from the alliances for the Ærfugl development. In addition the collaboration with Baker Hughes to enable the existing xmas threes to be reused at Ærfugl phase 2 has been key to enable the accelerated phase 2 start-up”, says Tom Storvik, Project Manager for the Ærfugl Field Development.

“The performance by the semi-sub alliance with Odfjell and Halliburton using the Deepsea Stavanger on Ærfugl, and the Modification alliance with Aker Solutions in collaboration with Kongsberg Maritime, has been very good as well. The early production start-up of from the first Phase 2 well shows how the alliances enable us to increase the value creation and to deliver in line with our ambitious improvement agenda,” Storvik adds.

FACTS ABOUT THE ÆRFUGL FIELD

- The Ærfugl reservoir is mainly a gas reservoir that extends over 60 km and is 2-3 km wide. The project holds a total of around 300 million barrels of oil equivalent.

- Ærfugl was first put on stream with the test producer A-1H in 2013 and has since produced via Skarv FPSO. Information gathered from this well proved good communication in the reservoir. This info was used to optimize the development of the Ærfugl structure with a total of seven wells.

- Total investment costs for the Ærfugl project (phase 1 and 2) are around NOK 8 billion.

- The total ‘life of field’ project has a break-even-price of around USD 15 per barrel (converted from gas). This makes the field development one of the most profitable being implemented on the Norwegian shelf.

- The Ærfugl project has brought significant local ripple effects for local suppliers in the Helgeland region.