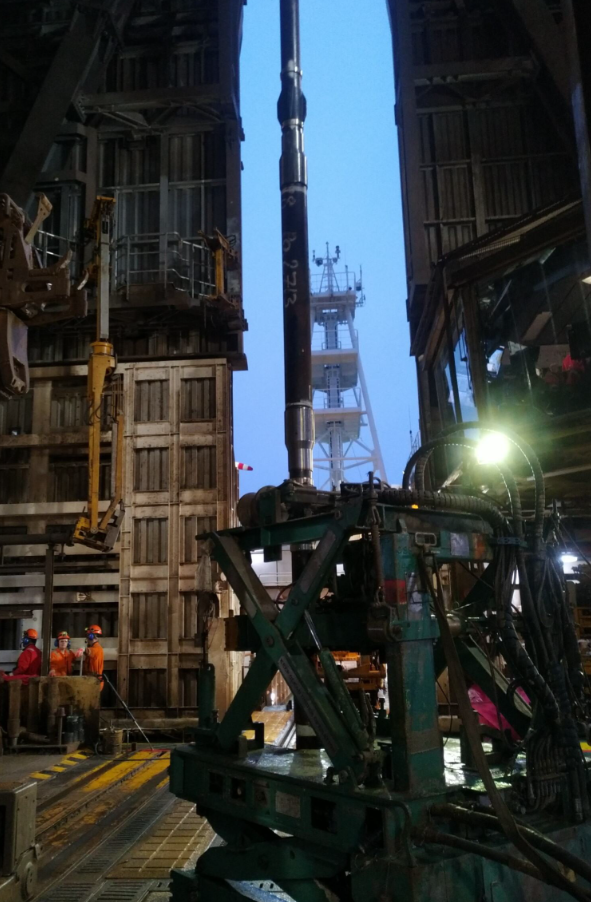

Aker BP has recently carried out an important pilot test of new well technology at the Alvheim field. HIPlog makes it possible to measure production down in the well without stopping production, and has been tested offshore for the first time.

This is the first time the technology has been installed offshore, and the initial results provide valuable insight.

“This project is first and foremost about gaining better insight into what is actually happening down in the well. With HIPlog, we obtain measurements that have previously been difficult or impossible to collect, especially in multilateral wells,” says Morten Hausken, Advanced Reservoir Engineer at Alvheim.

What is HIPlog?

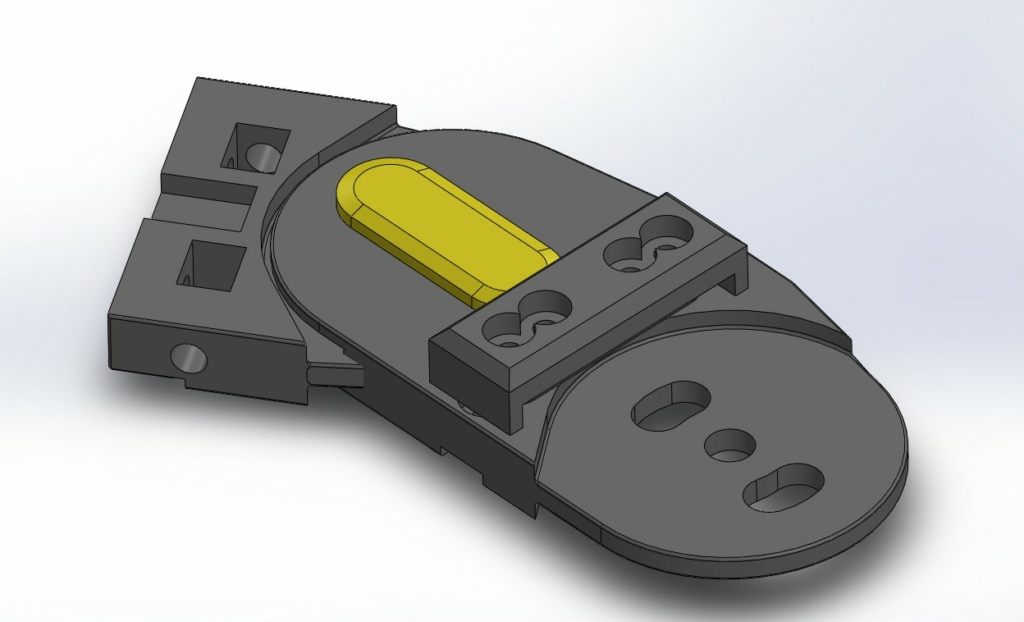

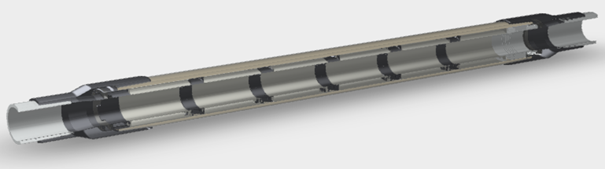

HIPlog is a wireless solution for measuring how oil and gas flow in different parts of a well.

In short, the technology works as follows:

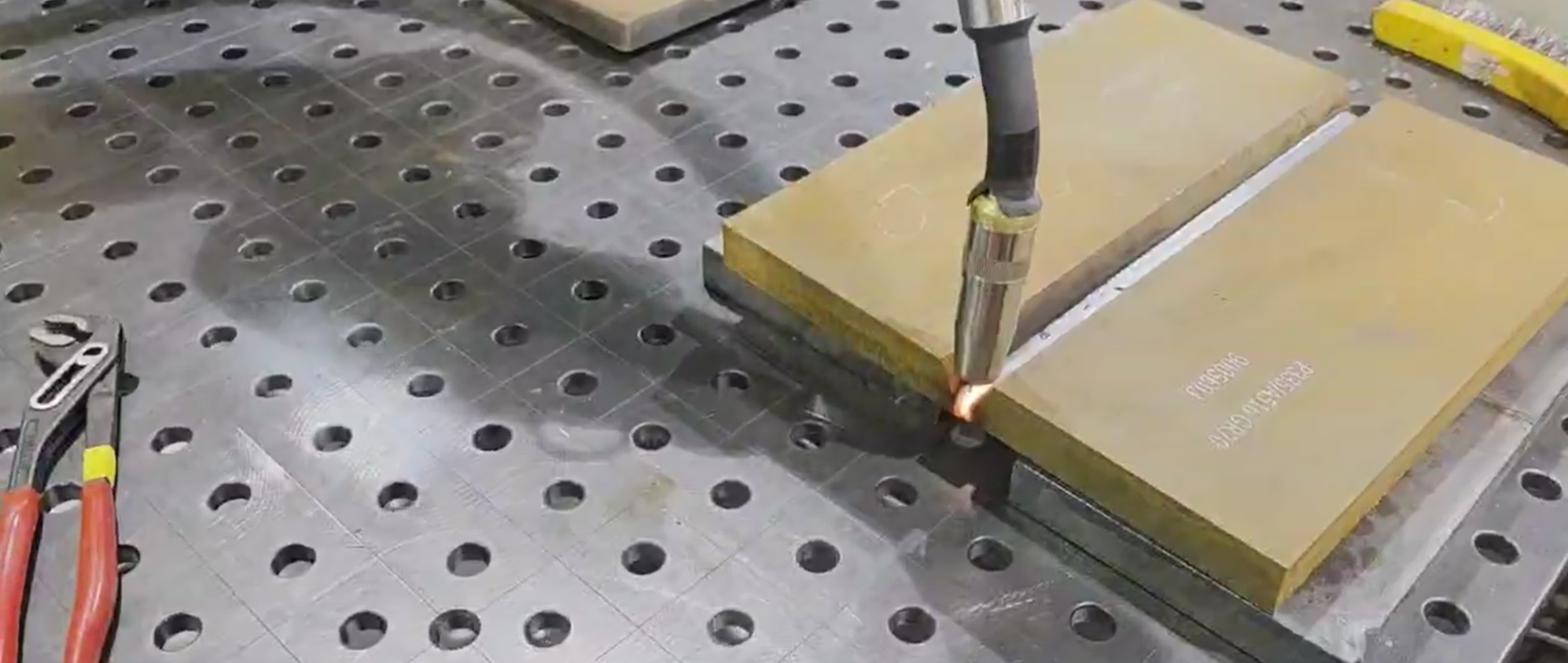

- Small heat sources are permanently installed in the well

- The sources send controlled heat signals into the flow

- Existing temperature sensors register the signals

- The data are used to calculate the production contribution from each branch and zone

Everything happens without cables, without interfering with production, and without additional well operations.

“The fact that we can obtain detailed production information without disrupting operations is ‘the very core of what HIPlog is developed for’,” says Tore Ottesen, Chief Executive Officer at Wellstarter, which delivers the service.

Why is this important?

In modern wells, and especially in multilateral wells, it is often challenging to gain an overview of how production is actually distributed.

HIPlog helps answer questions such as:

- Which branches produce the most

- How production changes over time

- If certain zones contribute less than expected

This insight can be used for:

- improved well management

- more targeted measures at the right time

- increased recovery over the well’s lifetime

“This is a good example of how we work with new technology at Aker BP. It is the result of several years of systematic technology development and qualification,” says Yngve Johansen, Subsurface R&D Manager.

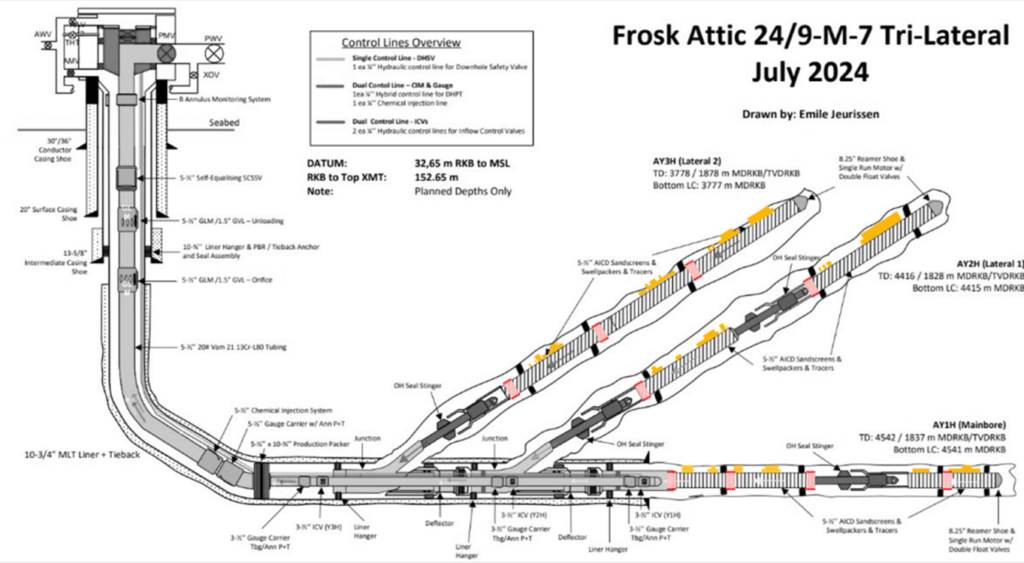

The pilot test at Alvheim

The pilot has been carried out in the Frosk Attic 24/9-M-7 well, which has three branches. In total, nine HIPlog stations are installed, three in each branch.

The first measurement campaign was conducted in November. The analyses show:

- clear and measurable signals from the technology

- production contributions from all three branches

- good measurement quality in two of the branches

- greater uncertainty in one branch, related to well geometry and low rates

“The pilot has provided us with good signals, but also important learning points. Among other things, we see how sensitive the setup is to low rates and distance between measurement points. This is knowledge we take forward,” says Hausken.

More data on the way

This is just the first step. The HIPlog installation is planned to be used over several years, with repeated measurements that will provide a better basis for comparison and clearer trends.

The next measurement round starts at the beginning of January and will contribute to:

- better understanding of the well’s development

- more reliable assessments of production contribution

- higher quality of analyses over time

“It is important to remember that this is early in the well’s life. As we obtain more measurements over time, the data foundation will continuously improve,” says Hausken.

A collaboration built over time

The project is based on several years of thorough preparatory work. The Edvard Grieg team and the JIP collaboration carried out much of the early technology work before the pilot at Alvheim. Aker BP has continued this work through qualification and practical implementation, with a clear focus on reducing risk for the well.

“For us, it has been crucial to test new technology in a controlled way, with a clear focus on well integrity and operational risk. The pilot at Alvheim shows that this is feasible in practice,” says Johansen.

“To be able to develop and test new technology, we are completely dependent on clear sponsors and support from field management. In this project, the support from Anne Skjærstein as sponsor from PE Excellence, the early development work Grethe Schei took part in at the ring source, and not least the anchoring with Alvheim AMT, have all been decisive. When leaders understand technology risk and at the same time dare to pilot new technology, this is how we make it happen in practice.”

The way forward

The pilot demonstrates that HIPlog functions as intended and provides real value. At the same time, this is new technology, and the experiences from Alvheim are expected to be important for further use, both at this field and in future wells.

“This is an important milestone for HIPlog. The fact that the technology is now installed offshore and performs as expected is the result of close collaboration and thorough preparation,” says Ottesen.

More information and updates are expected when the next measurement round has been fully analysed.