Aker BP, Schlumberger and Stimwell Services establish Well Intervention and Stimulation Alliance to accelerate and boost oil production.

OSLO, October 30, 2019

The 5+5 year tripartite agreement was signed by the CEOs of the three alliance partners at a venue at Aker BP’s Headquarter at Fornebu Tuesday 29 October.

Through collaboration, innovative technologies and digitization the newly formed Alliance endeavors to completely transform conventional intervention operations with clear targets of propelling hydrocarbon production on new and existing assets on the Norwegian Continental Shelf.

The Alliance focus will span interventions operations, with Schlumberger as partner for wireline logging, perforation and well stimulation through digital slickline, coiled tubing and flowback operations on Aker BP’s fixed installations, and StimWell as partner for vessel-based stimulation services.

Digital technology is fundamentally changing the industry, and the intervention space is no exception. The Well Intervention and Stimulation Alliance collaboration model accelerate access to digitized cloud computing, artificial intelligence, machine learning, proprietary technologies, integration of data with petrotechnical expertise and digital models, to overcome challenges and realize full production potential throughout life-of-field.

Karl Johnny Hersvik, the CEO of Aker BP said:

«These are exciting times. Aker BP is committed to increase the productivity, quality, flow- and time efficiency throughout the value chain. Strategic alliance relationships are an integral part of this strategy, thus I am pleased to enter the Well Intervention and Stimulation Alliance with Schlumberger and Stimwell Services.Multiple wells on Aker BP operated assets are on a fast-tracked schedule to be put on production adding a significant number of barrels to the Company’s total hydrocarbon output. By leveraging the combined digital horsepower from the parties, we have a unique opportunity to pave ahead and transform the well interventions space and ultimately generate value through increased oil production.»

Olivier Le Peuch, the CEO of Schlumberger added:

«This Alliance is a great example of a collaborative approach to drive customer performance by applying leading digital, subsurface technologies, and domain expertise in well intervention and stimulation operations to maximize production potential. We are committed to deploying Schlumberger’s unique team and technology performance, centered on our customer’s challenges, to drive efficiency sustainably for the benefit of our Alliance partners.»

Sami Haidar, the Managing Director of StimWell Services said:

«Through close alignment of supplier corporate objectives I am certain that this ground-breaking Alliance model will become in time the high-quality benchmark for the industry. In addition, by facilitating a collaborative approach, drawing on the combined knowledge of each of us, it will not only undoubtably deliver higher well productivity at a lower cost but will enable us to continue to raise the bar in terms of environmental best practice.»

The Well Intervention and Stimulation Alliance will host a network of personnel from the Alliance Members’ organizations, collocated at Aker BP offices in Jåttåvågen in Stavanger utilising a brand-new state-of-the-art Onshore Collaboration Centre, fully enabled for bidirectional data live feed with the offshore operations for 24/7 real-time support and decision making.

For further information, contact:

Ole-Johan Faret

Press Spokesman

AkerBP

+ 47 402 24 217

ole.johan.faret@akerbp.com[/vc_column_text][/vc_column][/vc_row]

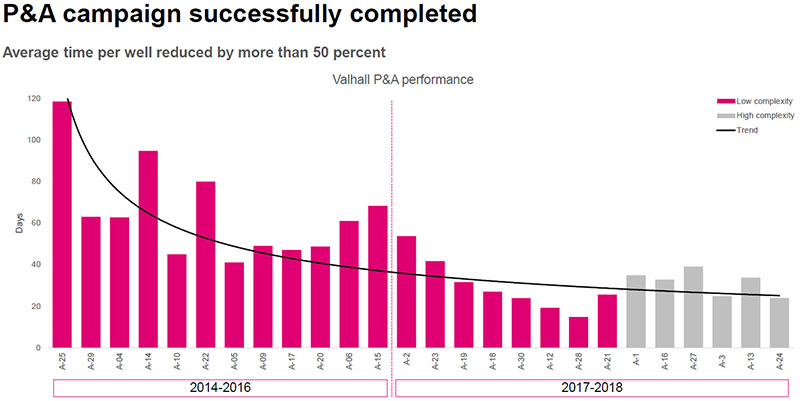

Maersk Invincible has completed the plug and abandonment (P&A) programme of wells at the Valhall field centre much sooner than planned, with no harm to people, equipment or the environment – and zero CO2 and NOx emissions.

Maersk Invincible has completed the plug and abandonment (P&A) programme of wells at the Valhall field centre much sooner than planned, with no harm to people, equipment or the environment – and zero CO2 and NOx emissions.

Maersk Drilling and Aker BP have agreed to a one-year contract to deploy high-performance rig Maersk Integrator on the Norwegian shelf from June 2019. The contract is founded on the alliance that the parties entered into in 2017.

Maersk Drilling and Aker BP have agreed to a one-year contract to deploy high-performance rig Maersk Integrator on the Norwegian shelf from June 2019. The contract is founded on the alliance that the parties entered into in 2017.