Extending Valhall’s lifetime with well plugging

Plugging of wells at the Valhall field centre has been completed six years earlier and more than five billion Norwegian kroner cheaper than originally planned. The work has also been delivered without serious incidents. Plugging wells is a key part of the modernisation of the Valhall field centre, and thus also in the ambition to produce a total of two billion barrels from the giant in the North Sea.

The Maersk Invincible drilling rig left the Valhall field centre last week. That marked the end of several years of plugging operations on the field. A total of 30 old wells from the original drilling platform (DP) have been plugged over the course of three campaigns since 2014.

Removing and renewing

Aker BP is operator and Pandion partner in Valhall. First oil flowed from the field in 1982. Since then, over a billion barrels of oil equivalent have been produced from the area – more than three times as much as expected at start-up.

The original QP accommodation platform was removed in the summer of 2019. Over the course of the next few years, the original drilling platform and process platform will also be removed from the field centre. The original Hod wellhead platform, south of the Valhall field, will also be removed and replaced with a new.

Safe and efficient

The first plugging campaign in 2014-2016 was conducted by the Maersk Reacher rig. Maersk Invincible carried out the last two campaigns in 2017-2018 and in 2020-2021.

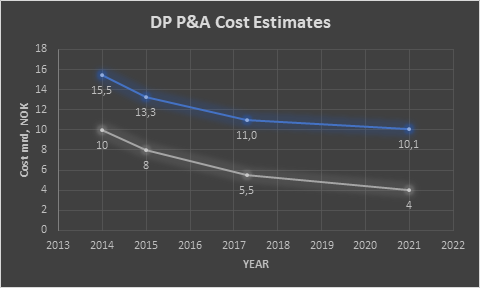

Originally Aker BP estimated the operational time of the plugging campaigns to 10 years at a cost of NOK 15.5 billion. The work was completed in 4 years and at a cost of NOK 10.1 billion.

World-class alliance deliveries

Reorganisation of the value chain through strategic partnerships and alliances is a core part of Aker BP’s strategy. The last plugging campaign on Valhall was delivered by the jack-up rig alliance between Maersk Drilling, Halliburton and Aker BP from September to March.

The original plan was to spend 72 hours per well to plug the top well section. During this winter, the alliance reduced this to as little as 33 hours. Overall, the alliance has delivered the entire scope of work more than two months faster than planned. Because of this, the Valhall asset team was able to rapidly mature a decision on new wells on Valhall Flank North, which means more work for the alliance.

“This shows what we are capable of delivering when we work as one team in the alliance model, alongside the best suppliers in the industry. Together we can exploit the maximum potential of the rig, and constantly push the limits of what we thought was possible,” says Sigmundstad.

“We’re seeing impressive results in the alliance, and this is just the beginning. What really sets the alliance apart from traditional cooperation models, is that we have shared incentives. This way of working results in greater confidence and stronger cooperation. Together, we can increase the efficiency of our operations. It’s a win-win situation, both in the short and longer terms, where we together can create more investment opportunities and even more innovation,” says Chief Operation Officer Morten Kelstrup from Maersk Drilling.

Short path to implement new technology

Valhall receives power from shore and has close to zero emissions of CO2 and NOx during normal production. Maersk Invincible has received its power supply from the Valhall field during both its plugging campaigns. Electrification of the rig has been a pioneering project for Aker BP, in line with the strategy to develop solutions that contribute to minimise the environmental footprint of our activities.

Aker BP also works actively to utilise market-leading technology that can result in lasting improvements in the operations, and thus also increased value creation. Several new technologies have seen the light of day in the plugging work – on a worldwide basis.

“The plugging team was given the authority and the funding to start using new technology. We have looked at technology that can contribute to faster, safer and more sustainable plugging of wells. The drivers behind this development have been engineers who have seen a need, found a technology, and contributed to develop it. The road from concept to implementation has been consistently short,” says Martin Straume, the company’s chief engineer for well plugging and abandonment.

Technology within well intervention has been implemented where possible. Nature’s own material, clay, a so-called “shale barrier”, has been used in connection with plugging operations.

“Section milling of cemented casing has been carried out inside larger casing. We have done this to verify that well barriers are in place on the outside of the conductor. This means that we have avoided having to mill or pull entire sections of casing from the surface and down to the relevant depth. This represents up to several weeks of time saved per well, and is an enormous improvement in the plugging work,” says Straume.

The top section of the old Valhall wells have been plugged using bismuth technology. This ground-breaking technology developed by BiSN helps to solve the challenge of potential methane leaks from old wells, and results in lower CO2 emissions compared with cement.

For the first time ever worldwide, Aker BP along with Halliburton and Maersk Drilling has conducted fully automated cementing operations from land. This took place from Aker BP’s offices in Stavanger. The technology increases efficiency, reduces costs and lowers HSE risk.

Preparing Valhall for the future

A little more than one year ago, the first oil flowed from Valhall Flank West. In March 2021, a new Hod platform is nearing completion at Aker Solutions’ yard in Verdal. The concept, implementation model and organisation for the Hod project were copied from Valhall Flank West. Planned production start for Hod is in the first quarter of 2022, and recoverable reserves are estimated at around 40 million barrels of oil equivalent. Aker BP has also now embarked upon studies for a new central platform on Valhall, which will ensure production capacity for future volumes in the area.

“Through new projects like this and the ongoing modernisation of the area we continue to increase value creation from Valhall. This not only creates substantial values for Aker BP and our owners, but also for the greater society through the taxes we pay, and by maintaining a world-class supplier industry,” says SVP Operations & Asset Development Ine Dolve, and concludes:

“I want to extend a big thank-you to everyone who has contributed to the work to plug wells on Valhall. The operation has been conducted efficiently and safely, and through this effort you are all contributing to prepare the giant Valhall for many more years of production.”