Tambar Crane Back in Operation Thanks to 3D Printing and Solution-Oriented Collaboration

Tambar is a remotely operated wellhead platform connected to Ula. When an incident put the offshore crane on Tambar out of service, the operations team faced a critical challenge: several damaged parts in the drag chain and an estimated delivery time of six weeks for new components from a factory in Italy. A production shutdown was not an option, they needed a smarter solution.

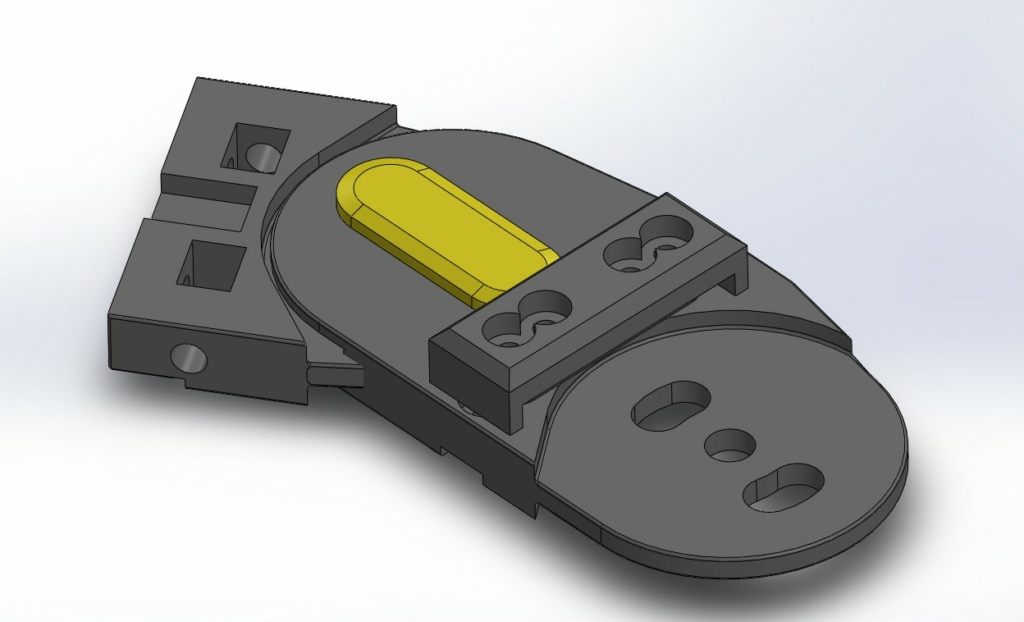

The challenge was to get the crane operational again. This required, among other things, 320 spacers, 160 separators, and 25 drag chain links. A traditional order would have taken weeks, but the team decided to think differently.

The solution was that a creative process operator 3D-modeled the drag chain links offshore, while the remaining parts were modeled onshore. Using 3D printing, they produced all the components within 24 hours.

“The offshore team then spent several days repairing damage, assembling, and installing the parts,” says Mariann Laursen Scotland, who works in crane and lifting on Ula.

As a result, the crane was quickly back in operation, and Tambar avoided a production shutdown. This is a clear example of what happens when skilled professionals dare to try new technology and collaborate across sea and land.

“I am very proud of the Ula/Tambar team for taking responsibility, being curious, and finding smart solutions when it matters most. This is the result of great collaboration across sea and land. We are in late-phase operations, but we remain eager to try new technology, and this is an excellent example of that,” says Talar Arif, SVP for Ula.