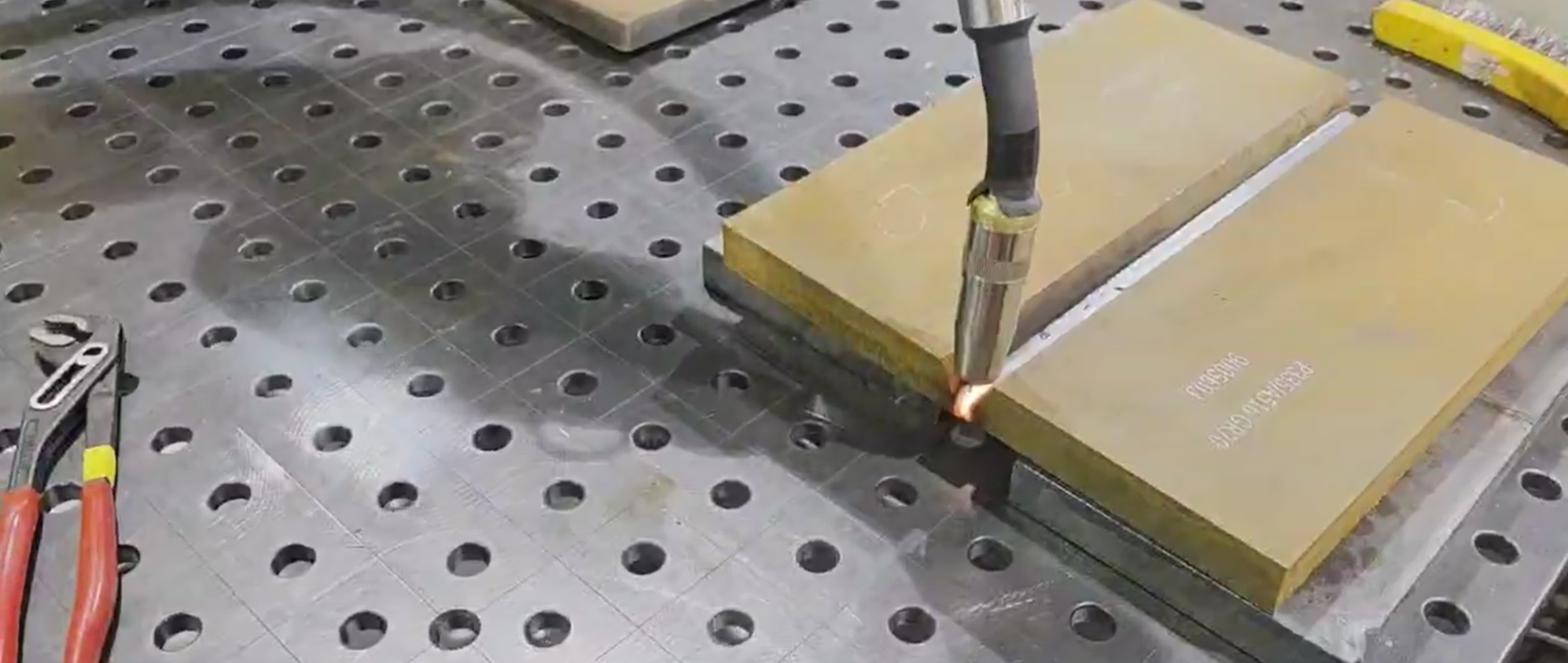

Successful pilot test of digital, robotic welding in confined areas

On Thursday 18 December, Aker BP conducted a successful pilot test with partner Effee. Here, digital, robotic structural welding was tested in confined areas. The new technology makes it possible to monitor the welding process in real time, which reduces the risk of errors and provides better control over quality.

The solution offers several important benefits: increased safety, higher quality, faster execution and lower costs. At the same time, it facilitates smarter and more needs-based maintenance going forward.

“The test was successful because we have worked purposefully and closely together across disciplines and departments. The result marks an important step in the digitalisation of welding processes offshore,” says project manager at Aker BP, Aslak Næss.

The collaboration with Effee started on Alvheim, where Roy Andre Erland took the initiative to use Effee’s solution for robotic welding of thin hull plates facing the sea. This quickly developed into an interdisciplinary qualification process, and new projects with strong contributions from Integrity, Future Operations, the central technology team and the modification alliance, which requested the pilot.

“In addition to the work on Alvheim, Aker BP and Effee intend to further develop a method for swivel repairs on Skarv,” says Næss.

“Now the goal is to realise even greater benefits through fully digital welding offshore, also in the modification alliance. Robotic, digital welding fits very well with our operational strategy.

Benefits of digital, robotic welding

- Fewer days without production: More efficient execution and reduced downtime through digitalisation and remote control.

- Significantly reduced POB: Welding specialists can control the process from shore, freeing up offshore capacity.

- Improved HSE: Welders can work from safe areas, and the use of inert gas in habitats further reduces exposure.

- Decentralised operating model: Offshore personnel handle rigging and preparations, while specialists control the welding process from shore.

- Simplified planning and documentation: Digitalisation provides better support for planning, execution, inspection and documentation.

“The fact that we have come so far in such a short time is a result of targeted use of R&D funds and a strong One Team collaboration between Effee, assets, functions and central technology in Aker BP,” says Næss.

Aker BP has now entered into a framework agreement with Effee for further R&D, and is in the process of establishing similar agreements for commercial assignments.