Milestone Marked for 1000-Ton Module for New Valhall Platform

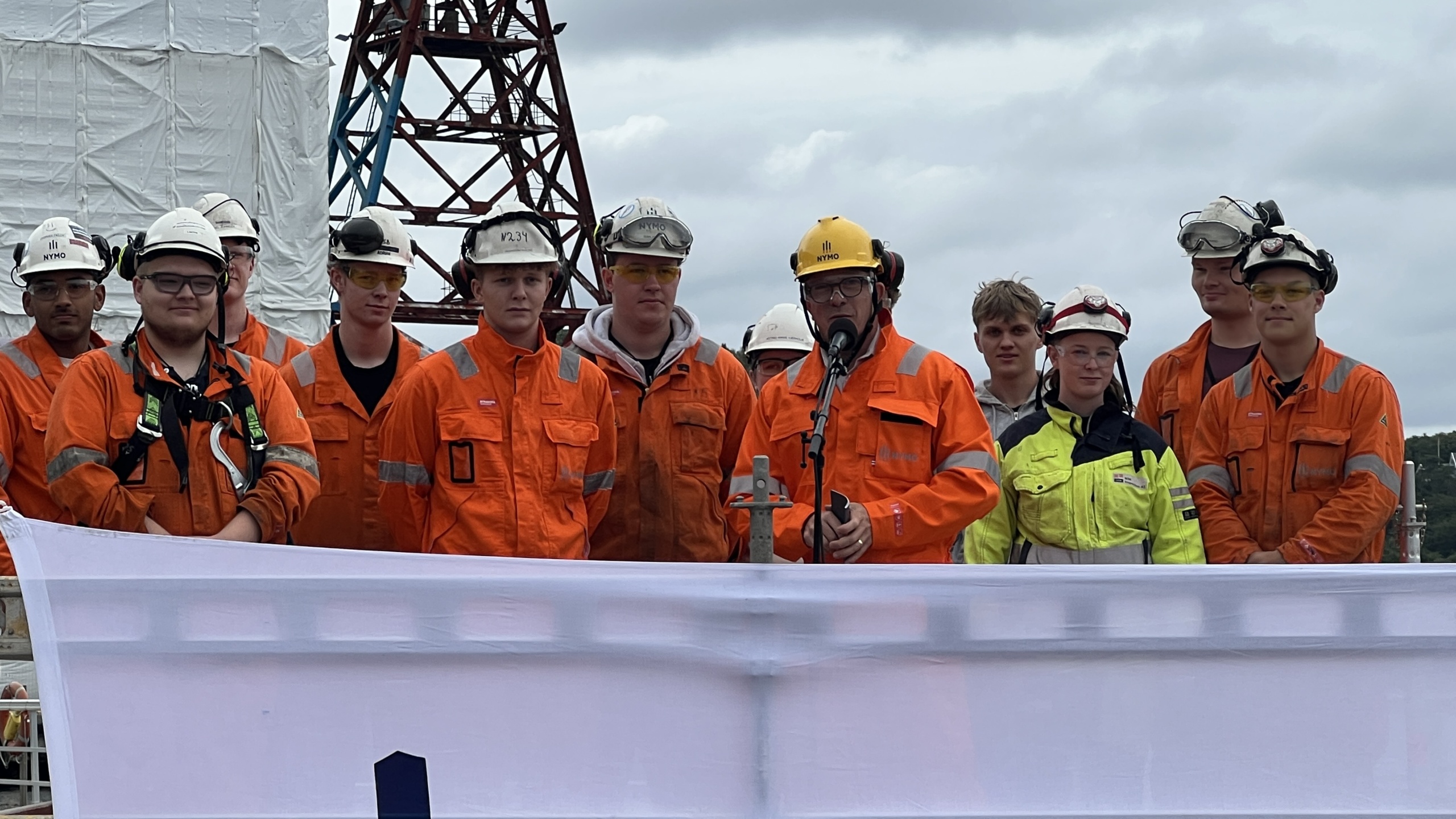

On August 11th, Aker BP, together with NOV and Nymo, celebrated an important milestone in the Valhall PWP project: the completion of equipment installation on the 1000-ton MEG module being built at Nymo’s yard in Grimstad.

Among the several hundred skilled workers attending the event were Grimstad Mayor Beate Skretting, Nymo owner Knut Ugland, Head of NOV’s Process Systems division Rune Fantoft, Project Director for Valhall PWP-Fenris Rannveig Storebø, and Aker BP CEO Karl Johnny Hersvik.

Local Ripple Effects

“This is a landmark day for Nymo and the entire Southern Norway region. The project has brought record-high activity to our workshops in Grimstad and Arendal. Most notably, we’ve tripled the number of apprentices—from 7 to 20—which strengthens recruitment into the industry,” said Nymo CEO Øyvind Boye.

In addition to the MEG module, Nymo has also built the bridge that will connect the new platform to the existing Valhall field center. The bridge, weighing around 1200 tons, was completed and transported from Nymo’s facility at Eydehavn in Arendal to the field in June.

The projects have had significant ripple effects for the local business community. Goods and services worth over 600 million NOK have been purchased from local companies.

“At times, more than 800 employees have been present at our facilities in Grimstad and Arendal simultaneously. This illustrates both the complexity and the tremendous boost these projects have given to the region’s industry,” said Boye.

Efficient One-Team Collaboration

The MEG module is a central part of the Valhall PWP development, where Aker BP is the operator. The module will enable the recycling of monoethylene glycol (MEG) in pipelines between Valhall and the Fenris field, located 50 kilometers away. This prevents hydrate formation and ensures efficient operations.

NOV Process Systems is the main supplier of the MEG module and has delivered the design, fabrication engineering, and procurement of all key equipment. Nymo, contracted by NOV, has been responsible for fabrication and completion. This is the first MEG regeneration system ever fabricated in Norway.

“We are proud and pleased to deliver this project with Aker BP, Nymo, and other partners and suppliers. MEG regulation systems are among the most technically advanced process technologies required for offshore gas production. Completing this project with fabrication in Norway, and continuing collaboration with Aker BP as the technology is deployed at Valhall, is a major milestone for us,” said Rune Fantoft of NOV. He emphasized that Aker BP, NOV, and Nymo have worked closely and integrated as one team to achieve this project milestone.

Production start in 2027

The MEG module will be completed and prepared for transport during the year and shipped to Aker Solutions’ yard at Stord early next year for finalization. The platform will then be installed at the Valhall field. Production start is planned for the second quarter of 2027.

“Valhall PWP-Fenris is one of the largest ongoing development projects on the Norwegian continental shelf. We are proud that so much of the work on PWP-Fenris is being done in Norway, especially in Southern Norway. This brings significant ripple effects to the local business community and contributes greatly to competence development in the industry,” said Project Director Rannveig Storebø of Aker BP.

The Valhall PWP-Fenris project is part of a comprehensive execution plan for Aker BP. In total, the company is investing around USD 20 billion in the development of new and existing fields on the Norwegian continental shelf.