Sustainability

Read our Sustainability report for 2023 and learn about our efforts to reduce emissions and contribute to a better society.

Our approach to sustainability

Aker BP takes global climate challenges seriously and works to reduce the company’s environmental footprint. Our emissions are less than one-third of the average in the global industry, and below the average for operators on the Norwegian continental shelf. Our GHG intensity target is set at below 4 kg CO2e per barrel of oil equivalent.

Our strategy to meet the world’s growing energy needs while also contributing to reducing global emissions is threefold: We aim to produce the cleanest oil and gas, and at the same time generate revenue that can be used to finance the energy transition and build a sustainable future.

Aker BP creates substantial long-term value from the natural resources available to us – thus enabling society to restructure the economy and introduce measures that can halt climate change. By reducing emissions from our activities, we contribute to a reduced global footprint. We also contribute knowledge, data and experience to new industries, creating growth and improvement beyond our own business.

United Nations Sustainable Development Goals

Aker BP’s core business of delivering energy to our customers and the way we operate contribute directly to and support several of the United Nations Sustainable Development Goals (SDG). Some of our main contributions are outlined in our sustainability report and illustrated below.

Human rights

Aker BP’s commitments to respect fundamental human rights and decent working conditions are set forth in our Code of Conduct and are further reiterated in our Human Rights policy.

To continuously improve our human rights efforts and avoid negative impact on fundamental human rights and decent working conditions, we conduct human rights due diligence in order to identify risks related to our operations.

Aker BP operates in a low-risk environment with respect to human rights as our main activities are in Norway, however we are mindful of the potential negative impacts from our operations and in our supply chain.

Governance policies

Climate

Aker BP acknowledges the conclusions from the Intergovernmental Panel on Climate Change (IPCC), and we are committed to take responsibility for the company’s carbon footprint.

We are convinced that we can and will be part of the solution needed to meet one of the biggest challenges of our time — climate change.

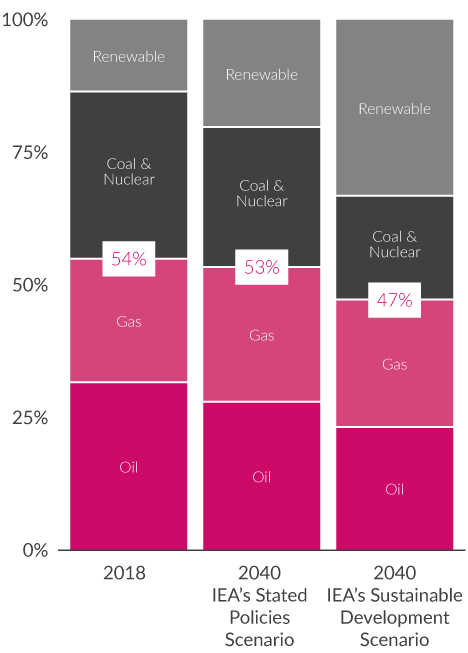

Towards 2030, global greenhouse gas emissions must be halved to succeed in halting global climate change. On the same horizon, we see that oil and gas will account for almost 50 per cent of the global energy mix in 2040, according to International Energy Agency (IEA) projections in the Sustainable Development Scenario. This scenario is fully aligned with the Paris Agreement on climate change.

By 2050, our gross Scope 1 and Scope 2 GHG emissions will be close to zero. This will be achieved through our investments in electrification and energy efficiency, as well as portfolio management. Read more about our approach to decarbonise our business in our climate transition plan.

Climate objectives and actions are formally embedded into Aker BP’s strategy and decision-making. The Board of Directors has ownership of climate-related objectives in Aker BP’s climate strategy, and reviews and guides the major action plans related to investment decisions for climate initiatives.

Climate transition plan

| Climate transition plan |

Environment policies

Environmental impact

Aker BP understands the environmental challenges presented by our activities and industry at large. Protecting the environment is and always has been a key part of sustainability work in Aker BP and we continuously work to reduce our environmental footprint. This work is guided by an environmental management system based on the principles of ISO 14001, and environmental management is integrated throughout the value chain of our fields.

Our Health, Safety, Security, Environment and Quality (HSSEQ) policy describes how to carry out our operations and our key environmental performance indicators guide our performance in a sustainable direction.

Our most significant environmental aspects originate from discharges to sea, emissions to air, waste, energy consumption and spills, and how these aspects affect biodiversity. We aim for an environmental impact that is as low as reasonably possible, through including use of best available techniques (BAT) and following NORSOK standard S-003 environmental care.

Key environmental performance indicators with corresponding targets, for instance for oil concentration of discharges to sea, CO2 emissions, flaring volume and produced water re-injection percentage, are defined at a company level and within each business unit.

Environment policies

Biodiversity

Aker BP’s exploration and production operations are concentrated in marine surroundings and we work efficiently to protect and conserve the related ecosystems and species within, thus safeguarding genetic biodiversity.

Activities in these areas are risk-assessed and monitored with regard to protection of sensitive benthic fauna and corals, coastal habitats, fish spawning and seabird breeding and feeding grounds.

Water and effluents

Aker BP’s operations are not located in water-stressed environments. All our operations are located on the Norwegian continental shelf, and freshwater usage is limited. Seawater is lifted and used for our operations such as cooling, pressure support for the reservoir and to generate fresh water offshore.

Our approach to generation and handling of effluents seeks the lowest possible environmental impact, with the following order of priority:

- Preventing occurrence

- Reuse/recycling/reinjection

- Reduction

- Treatment and disposal/discharge

Use of fresh water is limited, and mainly used at our supply vessels and in conjunction with drilling operations.

Data for consumption of fresh water from public sources are available in

this document.

Waste

In order to seek the lowest possible environmental impact, we believe that generating less waste and working for better resource utilisation is the most successful strategy.

Aker BP´s approach includes the following order of priority:

- Preventing occurrence

- Reuse/recycling

- Reduction

- Treatment and disposal/discharge

Aker BP’s waste handling processes follow relevant regulations for handling, storage, classification, labelling, transportation and declaration.

Oil spill response

History teaches us that oil spills can and do occur in our industry. Aker BP’s robust oil spill response includes trained personnel that work tirelessly to ensure sound preparations for and mitigation of possible oil spills. Risk assessments are performed, and emergency preparedness plans specifically for oil spills are in place.

Aker BP has participated actively in the Norwegian Clean Seas Association for Operating Companies (NOFO) since 2001. They are specially trained to manage oil spill response operations and assume a central role with regard to mitigation measures and oil spill recovery at sea. We work together with NOFO to ensure that our oil spill contingency measures are dimensioned for our needs, making sure that we are prepared at all times.

Circular economy

Aker BP shall implement circular economy initiatives along the entire value chain, both within the company and through supplier cooperation. We shall promote circular economy in processes and encourage sustainable consumption in our operations. We shall aim for reduced resource use and waste prevention, keeping resources in the economy for as long as possible.

Aker BP acknowledges the expectations towards a circular economy from regulators and other stakeholders. Our Circular Economy model emphasizes sustainable production and consumption, allowing us to increase resource efficiency and reduce waste generation.

Environment policies

Safe operations

A license to operate on the Norwegian continental shelf implies compliance with strict Health, Safety, Security and Environmental requirements from the Norwegian authorities.

Aker BP strives to ensure that all operations, drilling campaigns and projects are carried out under the highest HSSE standards. Our HSSEQ policy describes the standards and expectations to ensure that Aker BP is a safe workplace for both our employees and our contractors.

Social policies

Health and safety

Aker BP acknowledges that risks will always be present during our exploration and production activities. We see it as our responsibility to reduce this risk to as low as reasonably possible, to avoid that our activities have adverse effects on people, the environment, or financial assets. Identifying risk and most particularly, understanding risk are necessary to prevent accidents and to ensure adequate emergency preparedness and reduce uncertainty.

Our overall HSSE performance displays a positive trend. However, to meet our ambition of no harm to people we maintain our continuous efforts to seek improvements in our HSSE culture and management practices.

We have implemented a set of Life-Saving Rules from the International Association of Oil & Gas Producers. The “9 Life-Saving Rules” represent industry-wide best practice in preventive HSSE efforts.

Aker BP provides a set of both occupational and non-occupational health services to prevent, discover and monitor work-related health risks. Employees also receive non-occupational health services related to personal health, physical therapy and health-promoting services such as support for increased physical activity, dietary advice and stress management.

Social policies

Security

Aker BP takes a risk-based approach to how it conducts its business. To manage risks appropriately, the company must also account for risks that originate when malicious actors intentionally try to harm its interests. We call these “security risks” including cyber risk.

The purpose of security is to protect Aker BP’s material and immaterial assets from malicious actors and unintentional security incidents.

Audit and Risk Committee nominated on behalf of the board, oversee security with particular focus on cyber-security risk as part of their overall accountability towards risk governance and specific risks communicated through the Aker BP enterprise risk process.

The SVP HSSEQ, on behalf of the administration (Executive Management Team), is the overarching subject matter accountable for Security in Aker BP. The VP Security oversees Aker BP’s holistic security and is responsible for governing Personnel and Physical security. The Chief Cyber Security Officer is responsible for governing Cyber security. The VP Security and the Chief Cyber Security Officer coordinate company-wide security risk management and governance.

Deciding and funding implementation of security barriers and security controls according to governance and risk, is the responsibility of each business unit according to financial authorization matrix.

Social policies

Emergency preparedness

Aker BP has a robust and efficient emergency preparedness organisation. In the event of an unwanted incident, our most important tasks are to save lives and to minimise damage to the environment and assets.

The emergency preparedness organisation regularly undergoes training and conducts exercises to ensure it is prepared to handle situations that may occur.

We work closely with partners and other emergency response organisations to ensure a shared understanding of the emergency response plans, responsibilities and priorities. We exchange knowledge and experiences, because well-functioning emergency preparedness is in everyone’s interest.

Social policies

Sustainability reporting

Sustainability reports

| Annual report 2023 (including Sustainability report) | |

| Sustainability report 2022 | |

| Sustainability report 2021 | |

| Sustainability report 2020 | |

| Sustainability report 2019 | |

| Sustainability report 2018 | |

| Sustainability report 2017 |

CDP Climate

Aker BP participates in CDP (formerly the Carbon Disclosure Project). CDP is a not-for-profit charity that runs a global disclosure system for the benefit of society, investors, companies, cities and countries. Aker BP contributes to increased disclosure on climate as well as better access to information regarding how we work.

| 2023 – Aker BP CDP 2023 Climate Change Questionnaire | |

| 2022 – Aker BP CDP 2022 Climate Change Questionnaire | |

| 2022 – Aker BP CDP 2022 Climate Change Questionnaire Attachments | |

| 2021 – Aker BP CDP 2021 Climate Change Questionnaire | |

| 2020 – Aker BP CDP 2020 Climate Change Questionnaire | |

| 2019 – Aker BP Carbon Disclosure Project | |

| 2018 – Aker BP Carbon Disclosure Project | |

| 2017 – Aker BP Carbon Disclosure Project |

Sustainability data

Environment

302. ENERGY

| Energy consumption | 2021 | 2022 | 2023 | Units |

|---|---|---|---|---|

| Total fuel consumed from non-renewable sources (1*) | 18,604,936 | 16,804,039 | 13,772,679 | GJ |

| Energy consumption – gas | 16,201,143 | 15,288,587 | 11,947,952 | GJ |

| Energy consumption – diesel | 2,403,793 | 1,515,453 | 1,824,726 | GJ |

| Total fuel consumed from renewable sources | 0 | 0 | 0 | GJ |

| Electricity consumption (2*) | 417,001 | 417,144 | 884,395 | MWh |

| Electricity sold | 0 | 0 | 0 | MWh |

| Total energy consumption from non-renewable fuels and el. energy | 20,106,139 | 18,305,758 | 16,956,502 | GJ |

| Energy intensity ratio | 0.134 | 0.115 | 0.102 | GJ/boe |

2*Power consumption at office buildings, and power from shore to Valhall, Ivar Aasen and Edvard Grieg.

303. WATER AND EFFLUENTS

| 2021 | 2022 | 2023 | Units | |

| Produced water withdrawal total volume | 17,585 | 16,768 | 18,534 | 1000 m3 |

| Re-injected produced water volume | 10,712 | 10,898 | 12,919 | 1000 m3 |

| Percentage of produced water re- injected | 61 | 65 | 70 | % |

| Produced water discharged to sea volume | 6,767 | 5,726 | 5,389 | 1000 m3 |

| Percentage of produced water discharged | 39 | 34 | 29 | % |

| Hydrocarbon discharged to sea within produced water | 140 | 106 | 111 | tonnes |

305. EMISSIONS

| Scope 1 | 2021 | 2022 | 2023 | Units |

|---|---|---|---|---|

| Direct GHG emissions – all gases (3*) | 1,187,403 | 1,066,456 | 906,378 | tonnes CO2e |

| CO2 (Carbon dioxide) | 1,147,767 | 1,033,534 | 878,018 | tonnes |

| CH4 (Methane) | 1,250 | 1,026 | 867 | tonnes |

| N2O (Nitrous oxide) | 9 | 9 | 9 | tonnes |

| Methane Intensity (4*) | 0.03 | 0.02 | 0.01 | % CH4/saleable gas |

4* Expressed as volume methane emitted from operated assets as share of saleable gas production from operated assets (volume-based).

| Scope 1 emissions – by source | 2021 | 2022 | 2023 | Units |

|---|---|---|---|---|

| Flaring | 77,302 | 71,357 | 96,408 | tonnes CO₂e |

| Venting and fugitive emissions | 17,747 | 12,911 | 20,687 | tonnes CO₂e |

| Fuel combustion | 1,081,483 | 974,123 | 782,571 | tonnes CO₂e |

| Loading of hydrocarbons | 10,871 | 8,066 | 6,711 | tonnes CO₂e |

| Percentage of gross direct (scope 1) GHG emissions from CH₄ | 3.1% | 2.9% | 2.9% | % |

| Flared hydrocarbons | 26,021,456 | 23,213,472 | 30,752,742 | Sm³ |

| Other combustions | 372,312,461 | 359,129,046 | 284,005,667 | Sm³ |

| Continuously flared hydrocarbons | 0 | 0 | 0 | Sm³ |

| Vented hydrocarbons | 424,580 | 327,559 | 364,844 | Sm³ |

| Scope 2 | 2021 | 2022 | 2023 | Units |

|---|---|---|---|---|

| Indirect GHG emissions location based(5*) | 4,587 | 4,589 | 16,804 | tonnes CO2e |

| Indirect GHG Emissions – market based(6*) | 168,885 | 168,943 | 443,966 | tonnes CO2e |

6*Declaration of goods factor from NVE to calculate emissions: 502 g CO2e/kwh (2022 factor is used, as the 2023 factor is not available until mid-2024

| Scope 3 | 2021 | 2022 | 2023 | Units |

|---|---|---|---|---|

| Total GHG emissions | 64,237 | 63,054 | 72,607 | 1,000 tonnes CO2e |

| Upstream emissions(7*) | 470 | 264 | 302 | 1,000 tonnes CO2e |

| Downstream emissions(8*) | 63,768 | 62,789 | 72,305 | 1,000 tonnes CO2e |

8* Based on equity share.

| Reduction of GHG emissions | 2021 | 2022 | 2023 | Units |

|---|---|---|---|---|

| GHG emissions reduced as a direct result of reduction initiatives | 22,738 | 72,900 | 42,900 | 1,000 tonnes CO2e |

| GHG intensity | 2021 | 2022 | 2023 | Units |

|---|---|---|---|---|

| Scope 1 GHG emission intensity (Operational control) | 7.9 | 6.7 | 5.9 | tonnes CO2e/boe |

| Equity share Scope 1 and 2 GHG emissions(9*) | 366,120 | 393,052 | 479,155 | tonnes CO2 |

| Scope 1 and 2 GHG emissions intensity (equity share)(9,10*) | 4.8 | 3.7 | 2.9 | kg CO2/boe |

| Total GHG Emission intensity Scope 1-3 (Equity share)(11*) | 442 | 436 | 438 | kg CO2/boe |

10* Based on equity share of non-operated and operated assets calculated as a share of marketed equity share of oil and gas production.

11* Sum of equity share scope 1, 2, downstream scope 3, and operational control upstream scope 3 GHG emissions.

| Non-GHG emissions | 2021 | 2022 | 2023 | Units |

|---|---|---|---|---|

| NOX (Nitrogen oxide) | 1,684 | 1,814 | b | tonnes |

| SOX (Sulphur oxide) | 39 | 37 | 44 | tonnes |

| Non-methane VOC | 1,947 | 2,022 | 1,219 | tonnes |

| Biogenic CO2 emissions | – | – | – | tonnes CO2e |

306.WASTE

| 2021 | 2022 | 2023 | Units | |

|---|---|---|---|---|

| Total waste | 42,359 | 32,681 | 52,379 | tonnes |

| 2021 | 2022 | 2023 | Units | |

|---|---|---|---|---|

| Total weight hazardous waste | 40,516 | 31,203 | 50,580 | tonnes |

| Reuse | 506 | 352 | 112 | tonnes |

| Recycling | 1,800 | 1,689 | 2,631 | tonnes |

| Recovery, incl. energy recovery | 2,464 | 1,998 | 3,443 | tonnes |

| Landfill | 13,442 | 10,313 | 17,422 | tonnes |

| Discharge (12*) | 22,304 | 16,851 | 26,972 | tonnes |

| 2021 | 2022 | 2023 | Units | |

|---|---|---|---|---|

| Total weight non-hazardous waste | 1,843 | 1,478 | 1800 | tonnes |

| Reuse | – | – | 1 | tonnes |

| Recycling | 1,000 | 695 | 784 | tonnes |

| Recovery, incl. energy recovery | 724 | 698 | 879 | tonnes |

| Landfill | 119 | 84 | 135 | tonnes |

| Waste diverted from/to disposal | 2021 | 2022 | 2023 | Units |

|---|---|---|---|---|

| Total weight of waste diverted from disposal (13*) | 6,494 | 5,432 | 7,849 | tonnes |

| Total weight of hazardous waste diverted from disposal | 4,770 | 4,039 | 6,185 | tonnes |

| Total weight of non-hazardous waste diverted from disposal | 1,724 | 1,393 | 1,664 | tonnes |

| Total weight of waste diverted to disposal (14*) | 35,865 | 27,248 | 44,530 | tonnes |

| Total weight of hazardous waste diverted to disposal | 35,746 | 27,164 | 44,394 | tonnes |

| Total weight of non-hazardous waste diverted to disposal | 119 | 84 | 135 | tonnes |

14* Waste diverted to disposal includes waste that is discharged or sent to landfill.

| Significant Spills | 2021 | 2022 | 2023 | Units |

|---|---|---|---|---|

| Number of oil spills to sea (≥0,1 m³) | 0 | 3 | 1 | |

| Oil spills (≥0,1 m³) | 0 | 6.3 | 64.5 | m³ |

| Number of chemical spills to sea (≥0,1 m³) | 5 | 6 | 8 | |

| Chemical spills (≥0,1 m³) | 3.9 | 1.8 | 55 | m³ |

| Number of hydrocarbon leaks (≥0,1 kg/s) | 0 | 0 | 0 | |

| Total mass of hydrocarbon leaks (≥0,1 kg/s) | 0 | 0 | 0 | kg |

307. ENVIRONMENTAL COMPLIANCE

| 2021 | 2022 | 2023 | Units | |

| Total monetary value of significant fines | 0 | 1.1 | 0 | mill NOK |

| Number of non-monetary sanctions for non-compliance | 0 | 1 | 0 | 0 |

308. SUPPLIER ENVIRONMENTAL ASSESSMENT

| 2021 | 2022 | 2023 | Units | |

| New major suppliers screened using environmental criteria(15*) | 100 | 100 | N.A | % |

Occupational health and safety

| 2021 | 2022 | 2023 | Units | |

| Fatalities Employees | 0 | 0 | 0 | |

| Fatalities hired consultants | 0 | 0 | 0 | |

| Fatalities workers in the value chain | 0 | 0 | 0 | |

| Serious injuries employees | 2 | 0 | 2 | |

| Serious injury frequency hired consultants | 0 | 0 | 0 | |

| Serious injuries workers in the value chain | 2 | 3 | 3 | |

| Serious injury frequency employees | 0.6 | 0.0 | 0.5 | per million work hours |

| Serious injury frequency hired consultants | 0.0 | 0.0 | 0.0 | per million work hours |

| Serious injury frequency own workforce | 0.5 | 0.0 | 0.4 | per million work hours |

| Serious injuriy frequency workers in the value chain | 0.7 | 1.2 | 0.9 | per million work hours |

| Serious injury frequency – total workforce | 0.6 | 0.4 | 0.5 | per million work hours |

| Lost Time Injuries – employees | 1 | 0 | 2 | |

| Lost Time Injuries – hired consultants | 0 | 0 | 0 | |

| Lost Time Injuries – workers in the value chain | 6 | 5 | 8 | |

| Lost Time Injury Rate – employees | 0.3 | 0.0 | 0.5 | per million work hours |

| Lost Time Injury Rate – hired consultants | 0.0 | 0.0 | 0.0 | per million work hours |

| Lost Time Injury Rate – own workforce | 0.2 | 0.0 | 0.4 | per million work hours |

| Lost Time Injury Rate – workers in the value chain | 2.1 | 2.0 | 2.3 | per million work hours |

| Lost Time Injury Rate – total workforce | 1.0 | 0.7 | 1.1 | per million work hours |

| Medical Treatment Injuries – employees | 4 | 2 | 2 | per million work hours |

| Medical Treatment Injuries – hired consultants | 0 | 0 | 0 | per million work hours |

| Medical Treatment Injuries – workers in the value chain | 7 | 5 | 10 | per million work hours |

| Total Recordable Injury Frequency – employees | 1.6 | 0.6 | 0.9 | per million work hours |

| Total Recordable Injury Frequency – hired consultants | 0.0 | 0.0 | 0.0 | per million work hours |

| Total Recordable Injury Frequency – own workforce | 1.2 | 0.4 | 0.7 | per million work hours |

| Total Recordable Injury Frequency – workers in the value chain | 4.6 | 4.0 | 5.3 | per million work hours |

| Total Recordable Injury Frequency – total workforce | 2.6 | 1.7 | 2.4 | per million work hours |

| Serious incidents | 0 | 5 | 3 | |

| Serious incident frequency | 0.0 | 0.7 | 0.3 | per million work hours |

| Work hours employees | 3.1 | 3.5 | 4.3 | million hours |

| Work hours hired consultants | 0.9 | 1.0 | 1.4 | million hours |

| Work hours own workforce | 4.0 | 4.5 | 5.7 | million hours |

| Work hours workers in the value chain | 2.8 | 2.5 | 3.4 | million hours |

| Work hours total workforce | 6.9 | 7.0 | 9.1 | million hours |

| Asset integrity and process safety | 2021 | 2022 | 2023 | Units |

|---|---|---|---|---|

| Number of Tier 1 and Tier 2 Process Safety Events (PSE) | 0 | 0 | 1 |